Blog

- Home

- Blog

Understanding the Advantages of Hydraulic Diaphragm Pumps in Modern Industrial Applications

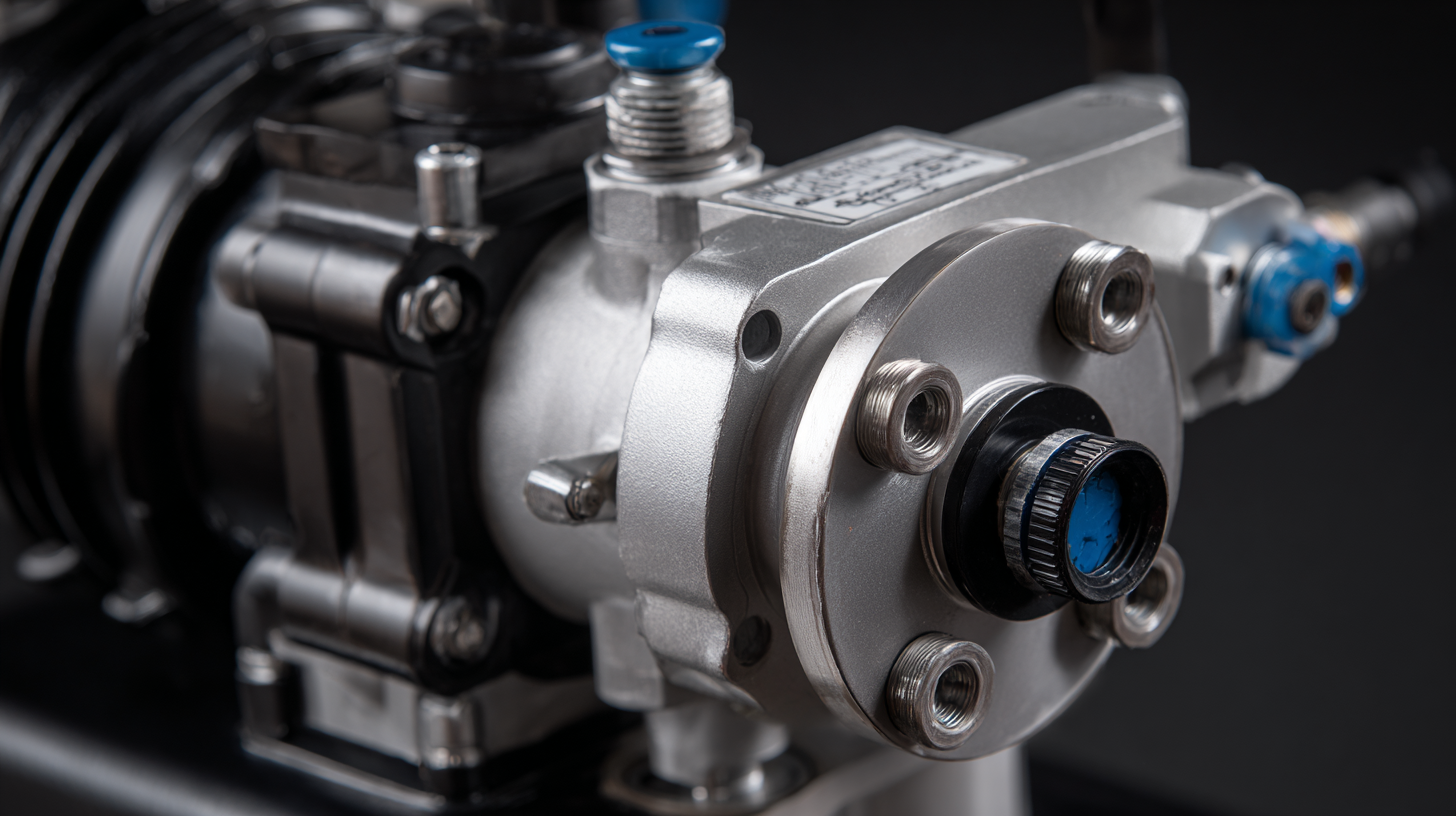

In recent years, the demand for efficient and reliable pumping solutions in various industrial applications has significantly increased, with the global diaphragm pump market projected to reach $8.5 billion by 2027, growing at a CAGR of 5.3%. Among the diverse options available, the Hydraulic Diaphragm Pump has emerged as a superior choice due to its unique design and operational advantages. Known for their ability to handle abrasive and corrosive fluids, these pumps provide exceptional sealing capabilities and reduce the risk of leaks, making them ideal for industries such as chemical processing, water treatment, and food manufacturing.

Furthermore, the hydraulic diaphragm pump technology enhances efficiency and minimizes maintenance costs, offering businesses a sustainable and cost-effective solution in today’s competitive market. This article will explore the myriad benefits of hydraulic diaphragm pumps and their role in driving innovation across modern industrial sectors.

Benefits of Hydraulic Diaphragm Pumps in Industrial Settings

Hydraulic diaphragm pumps have gained significant traction in industrial applications due to their unique advantages. One of the primary benefits is their ability to handle a wide range of fluids, including slurries, viscous liquids, and corrosive chemicals. According to a recent report by the Research Institute for Comprehensive Industrial Solutions, hydraulic diaphragm pumps can efficiently manage fluid delivery rates exceeding 300 gallons per minute while maintaining precise accuracy. This capability makes them invaluable in sectors such as oil and gas, pharmaceuticals, and wastewater treatment.

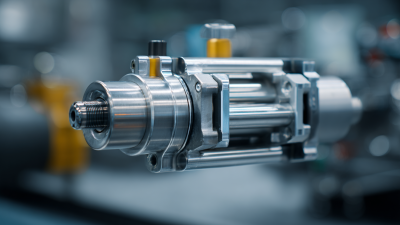

Additionally, the reduced maintenance requirements of hydraulic diaphragm pumps contribute to their popularity in modern industrial settings. The absence of dynamic seals, which are prone to wear and leakage, enhances their operational reliability. A study from the International Society for Fluid Power indicates that the maintenance interval for these pumps can extend beyond 8,000 hours under normal operational conditions. This not only leads to lower downtime but also results in significant cost savings, as companies can allocate resources towards more productive activities instead of frequent repair and replacement. This balance of efficiency and durability positions hydraulic diaphragm pumps as a prime choice for industries seeking to optimize their fluid management processes.

Operational Efficiency of Hydraulic Diaphragm Pumps in Various Industries

Hydraulic diaphragm pumps are gaining traction in various industries due to their excellent operational efficiency. These pumps excel in handling corrosive and viscous fluids, making them ideal for sectors such as chemical processing, food and beverage, and wastewater management. One of the key advantages is their ability to maintain a consistent flow rate, which is crucial for processes that require precise liquid transfer.

Hydraulic diaphragm pumps are gaining traction in various industries due to their excellent operational efficiency. These pumps excel in handling corrosive and viscous fluids, making them ideal for sectors such as chemical processing, food and beverage, and wastewater management. One of the key advantages is their ability to maintain a consistent flow rate, which is crucial for processes that require precise liquid transfer.

Tips: When selecting a hydraulic diaphragm pump, consider factors such as the fluid's properties, required flow rate, and pressure. This will ensure that you choose a pump that optimizes performance and enhances productivity in your specific application.

In addition to their efficiency, hydraulic diaphragm pumps are designed for longevity and minimal maintenance. Their unique construction allows for self-priming capabilities and reduces the likelihood of cavitation, which can lead to pump failure. Industries can benefit from reduced downtime and lower operational costs associated with maintenance, thereby improving overall productivity.

Tips: Regular inspections and adherence to manufacturer guidelines will significantly extend the lifespan of your pump, ensuring that it operates at peak efficiency throughout its service life.

Maintenance Requirements and Longevity of Hydraulic Diaphragm Pumps

Hydraulic diaphragm pumps are renowned for their efficiency and versatility in modern industrial settings, but their longevity is largely determined by proper maintenance practices. Regular inspection of key components, such as diaphragms and seals, is essential.

These parts are subject to wear and tear from the fluids being pumped, and any signs of damage should prompt immediate replacement to prevent operational failures. Additionally, routine cleaning of the pump system is crucial

to avoid the buildup of corrosive materials that can impact performance and durability.

Another critical aspect of maintaining hydraulic diaphragm pumps is monitoring the hydraulic fluid levels and quality. Ensuring that the hydraulic fluid is clean and within the appropriate levels not only enhances pump efficiency but also extends its lifespan. Moreover, periodic system checks, including hydraulic pressure evaluations, can preemptively identify potential issues before they escalate. By adhering to these maintenance requirements, businesses can maximize the operational life of their hydraulic diaphragm pumps, ensuring reliable performance in demanding industrial environments.

Comparative Analysis: Hydraulic Diaphragm Pumps vs. Other Pump Types

Hydraulic diaphragm pumps have gained a strong foothold in modern industrial applications due to their unique advantages when compared to other pump types. These pumps feature a diaphragm that separates the fluid from the mechanical components, minimizing the risk of contamination and wear. This design enhances their reliability, making them ideal for transferring aggressive or sensitive liquids in sectors such as pharmaceuticals, food processing, and chemical manufacturing. Unlike centrifugal pumps, hydraulic diaphragm pumps can handle varying flow rates and pressures, making them more versatile for specific applications.

**Tip:** When selecting a pump for your operation, consider the specific characteristics of the fluids being handled. Hydraulic diaphragm pumps excel in situations where precise flow control and minimal leakage are essential. Their ability to manage shear-sensitive fluids without causing damage adds to their advantage over gear and centrifugal pumps.

In terms of operational efficiency, hydraulic diaphragm pumps stand out with their energy-saving capabilities. They often require less maintenance than traditional pumps, due to their sealed design that reduces the risk of leakage and extends the lifespan of internal components. By investing in these pumps, industries can achieve greater productivity while minimizing downtime.

**Tip:** Regularly inspect the diaphragm and other components for wear, and schedule maintenance checks to ensure optimal performance. This proactive approach can prevent costly disruptions and ensure that the hydraulic diaphragm pumps continue to operate at peak efficiency.

Understanding the Advantages of Hydraulic Diaphragm Pumps in Modern Industrial Applications

Key Applications of Hydraulic Diaphragm Pumps in Modern Industry

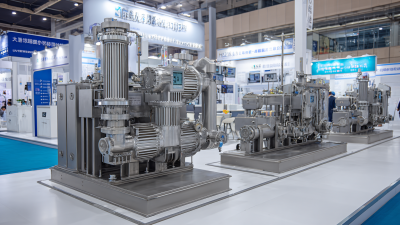

Hydraulic diaphragm pumps have gained significant traction in various modern industrial applications, primarily due to their versatility and efficiency. One of the key areas where these pumps excel is in the chemical processing industry. They can handle aggressive and viscous fluids with ease, making them ideal for transporting corrosive substances without the risk of leaks or contamination. Their ability to provide precise flow rates ensures consistent product quality, which is crucial in processes such as blending, mixing, and chemical reactions.

Another notable application of hydraulic diaphragm pumps is in the wastewater treatment sector. These pumps are particularly effective in managing slurries and thick liquids, ensuring smooth operation in environments prone to solids and varying viscosity. Their robust design allows them to maintain high performance even under challenging conditions, thus improving the overall efficiency of treatment processes. Additionally, their ability to self-prime and run dry enhances reliability, reducing downtime and maintenance costs in industrial operations.

Understanding the Advantages of Hydraulic Diaphragm Pumps in Modern Industrial Applications

| Application Area | Pump Capacity (L/min) | Pressure Range (bar) | Fluid Compatibility | Key Advantages |

|---|---|---|---|---|

| Water Treatment | 50 | 1-5 | Chemicals, Wastewater | Corrosion resistance, precise metering |

| Food Processing | 30 | 1-3 | Food grade liquids | Hygienic design, easy cleaning |

| Pharmaceuticals | 20 | 2-6 | Sterile fluids, chemicals | High precision, contamination prevention |

| Mining | 100 | 5-10 | Slurry, heavy liquids | Durability, handling abrasive materials |

| Chemical Processing | 80 | 2-8 | Acids, bases, solvents | Chemical resistance, variable flow rates |

Related Posts

-

Ultimate Guide to Selecting the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

Understanding the Benefits of High Pressure Diaphragm Pumps in Industrial Applications

-

How to Select the Best Piston Pump for Your Industrial Needs

-

5 Innovative Ways Pressure Pumps Enhance Industrial Efficiency