Blog

- Home

- Blog

Understanding the Benefits of High Flow Hydraulic Pump in Modern Industrial Applications

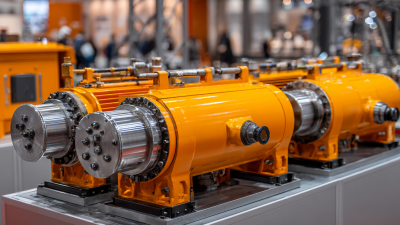

In today's rapidly advancing industrial landscape, the demand for efficient and reliable machinery has never been higher. One pivotal component that has garnered significant attention is the High Flow Hydraulic Pump. This technology is engineered to deliver superior performance by providing a substantial volume of hydraulic fluid at high pressure, thereby enhancing the operational capabilities of various industrial applications. Industries ranging from construction and manufacturing to automotive and energy are increasingly adopting high flow hydraulic systems to improve productivity and reduce downtime. By exploring the benefits of High Flow Hydraulic Pumps, we can better understand how they contribute to increased efficiency, reduced energy consumption, and overall operational excellence in modern industrial environments. This article delves into the transformative role of High Flow Hydraulic Pumps, highlighting their advantages and explaining why they are an essential investment for businesses aiming to thrive in a competitive marketplace.

Benefits of High Flow Hydraulic Pumps in Increasing Operational Efficiency

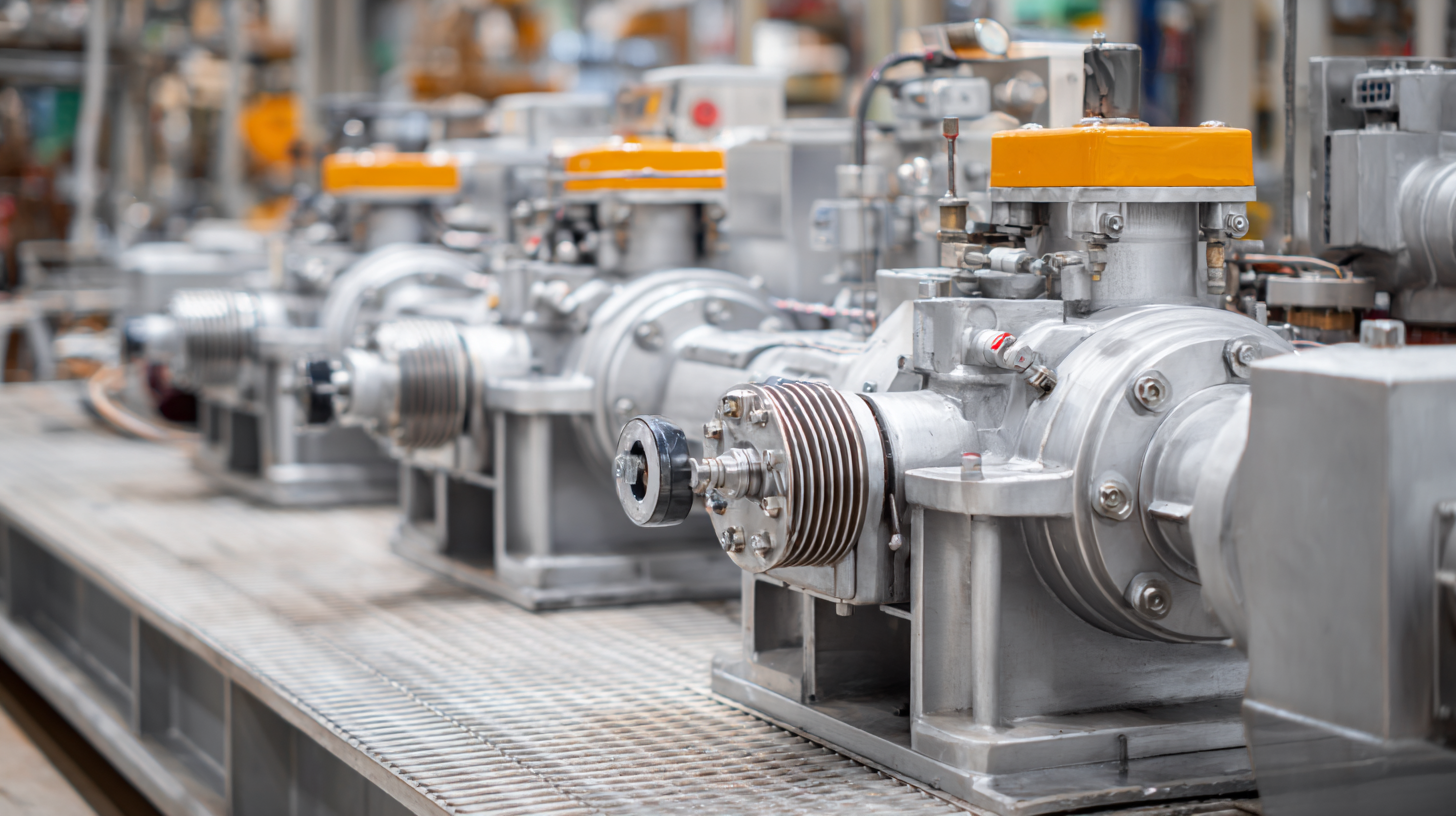

High flow hydraulic pumps have become essential in modern industrial applications, providing significant benefits in terms of operational efficiency. These pumps deliver a larger volume of fluid per minute compared to their standard counterparts, facilitating quicker and more effective machinery operation. This increased flow rate enables industries to complete tasks faster, such as lifting heavy loads, powering multiple hydraulic functions simultaneously, and reducing cycle times in manufacturing processes. As a result, businesses can achieve higher productivity levels while optimizing resource usage.

Tips: When selecting a high flow hydraulic pump, consider the specific demands of your application. Ensure that the pump's flow rate and pressure ratings align with your machinery requirements. Additionally, regular maintenance can prolong the life of your pump, ensuring it consistently delivers peak performance.

The transition to high flow hydraulic systems can also lead to energy savings. By operating machinery with a more efficient hydraulic pump, energy consumption can be minimized, allowing for reduced operational costs. Implementing these pumps not only boosts throughput but can also lessen the environmental impact by cutting down on energy waste.

Tips: Investing in a variable frequency drive (VFD) can further enhance the efficiency of your hydraulic system, allowing the pump to adjust its speed based on current demands, thus saving energy and extending equipment life.

Cost Savings through Enhanced Productivity in Industrial Applications

High flow hydraulic pumps are transforming modern industrial applications by significantly enhancing productivity, leading to notable cost savings. These pumps are designed to deliver a higher volume of hydraulic fluid, enabling machinery to operate more efficiently and perform tasks at a faster pace. As a result, industries can increase their output while minimizing downtime, ultimately reducing operational costs. By optimizing workflows, companies can allocate labor more effectively and reduce wear and tear on equipment, which prolongs machinery life and lowers maintenance expenses.

Tips: When considering the implementation of high flow hydraulic pumps, assess the specific needs of your machinery and operations. This ensures that the flow rate aligns with your productivity targets. Additionally, regular maintenance check-ups can help identify potential issues before they escalate, maintaining optimal performance and preventing costly repairs.

Investing in high flow hydraulic pumps not only improves efficiency but can also provide a competitive edge in the market. By enhancing productivity, businesses can fulfill orders faster, increase customer satisfaction, and potentially gain new clients, all while realizing substantial savings on energy and resources. Adopting this technology positions companies for success in an increasingly competitive landscape.

Tips: Collaborate with hydraulic system specialists to determine the best pump configurations for your applications. Proper installation and calibration can further maximize efficiency and ensure reliable performance over time.

Impact of High Flow Pumps on Fluid Control and Precision Engineering

High flow hydraulic pumps are increasingly vital in modern industrial applications, particularly in enhancing fluid control and precision engineering. With their ability to deliver substantial volumes of fluid at high pressures, these pumps are not only integral in manufacturing but also in advanced fields such as healthcare and biotechnology. For instance, mixed-flow pumps, which combine centrifugal and axial-flow characteristics, significantly affect inlet flow patterns and energy efficiency, leading to improved performance in various industries.

Tips: When selecting a high flow hydraulic pump, consider the application-specific requirements such as pressure, flow rate, and energy efficiency. Ensuring compatibility with existing systems can lead to smoother operations and enhanced productivity.

Recent studies underscore the importance of precision in fluid dynamics. For example, microchannel chips have emerged as essential tools in biomedical applications, allowing for tight control over fluid movement, which is crucial for accurate diagnostics and treatment customization. Additionally, advancements in microfluidics technology, including systems that enable pulse-free liquid delivery, further demonstrate how high flow pumps are revolutionizing fluid management in sensitive environments.

Tips: Always evaluate the latest technological trends and data reports in fluid dynamics to remain competitive and efficient in your industrial applications. Staying informed can help in making better design and operational choices.

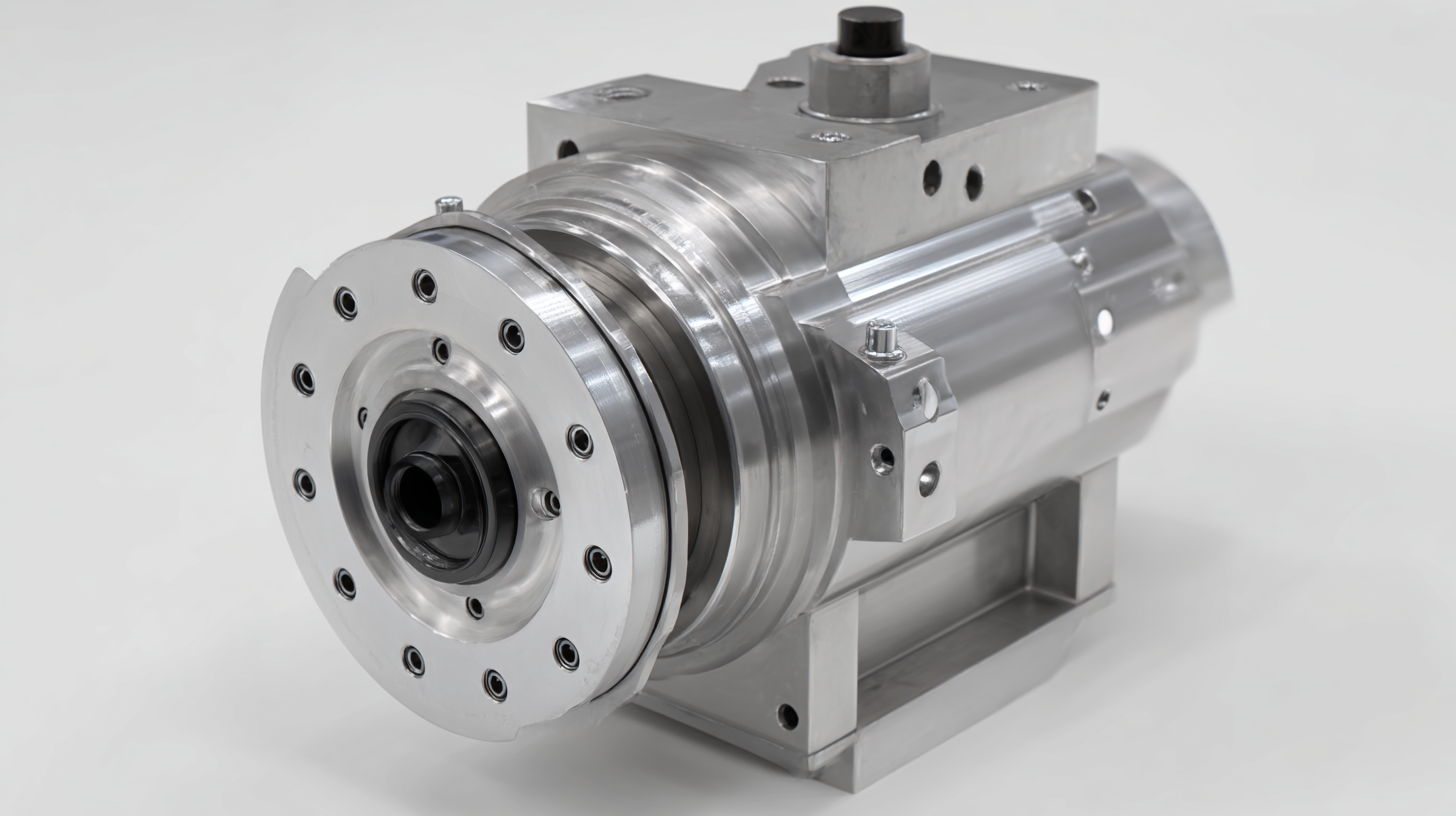

High Flow Hydraulic Pumps: Key Features for Modern Machinery Benefits

High flow hydraulic pumps play a crucial role in modern machinery, enhancing efficiency and performance across various industrial applications. These pumps are designed to deliver a significant volume of hydraulic fluid at high pressures, making them ideal for tasks that require rapid speed and power. Key features of high flow hydraulic pumps include advanced control systems, durable construction materials, and compatibility with a range of hydraulic fluids, ensuring optimal performance even in the most demanding environments.

High flow hydraulic pumps play a crucial role in modern machinery, enhancing efficiency and performance across various industrial applications. These pumps are designed to deliver a significant volume of hydraulic fluid at high pressures, making them ideal for tasks that require rapid speed and power. Key features of high flow hydraulic pumps include advanced control systems, durable construction materials, and compatibility with a range of hydraulic fluids, ensuring optimal performance even in the most demanding environments.

Tips: When selecting a high flow hydraulic pump, consider the specific requirements of your machinery. Evaluate the pump’s flow rate, maximum pressure, and compatibility with existing hydraulic systems to ensure seamless integration and maximum effectiveness. Additionally, regular maintenance is essential to prolong the lifespan of the pump and maintain its operational efficiency.

Moreover, high flow hydraulic pumps are typically equipped with improved filtration systems that enhance the quality of hydraulic fluid. This feature not only reduces wear on components but also increases the overall reliability of the hydraulic system. Industrial operators can benefit from understanding the key specifications and maintenance practices associated with these pumps to achieve optimal performance and reduce downtime in their operations.

Tips: Always follow manufacturer guidelines for maintenance schedules and operational checks. Consider investing in training for your staff to ensure they are competent in handling high flow hydraulic systems safely and effectively.

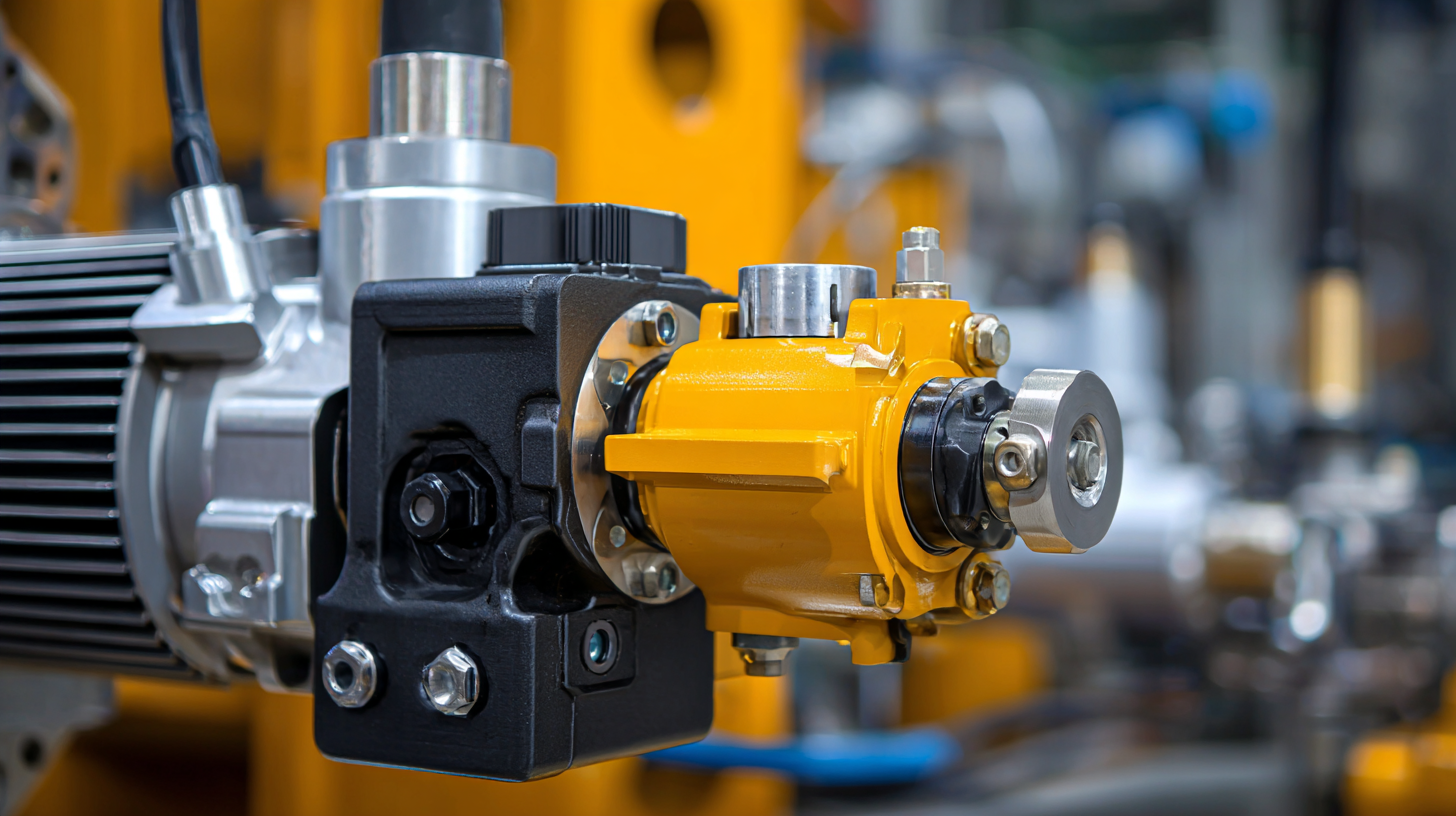

Applications of High Flow Hydraulic Pumps in Diverse Industrial Sectors

High flow hydraulic pumps play a crucial role across various industrial sectors, offering enhanced efficiency and performance in demanding applications. The construction industry, for example, leverages these pumps to operate heavy machinery and equipment, requiring significant hydraulic power to function effectively. According to a report by the International Federation of Hydraulic Engineers, high flow hydraulic pumps can improve operational efficiency by up to 30% in construction tasks, reducing downtime and increasing productivity.

In the manufacturing sector, these pumps facilitate processes such as material handling and molding. With the capacity to deliver fluid at high rates, they enable faster cycle times for machinery, directly contributing to increased output. A market analysis by Global Industry Analysts indicates that the demand for high flow hydraulic pumps is expected to grow at a CAGR of 5.3% from 2023 to 2030, reflecting their importance in maintaining competitive advantage in manufacturing operations.

Tip: When selecting a high flow hydraulic pump for your sector, consider the specific flow rate requirements of your machinery to ensure optimal performance.

Moreover, the agriculture industry has also started to embrace these pumps for applications like automated irrigation systems. Improved flow rates lead to better water distribution, crucial in maintaining crop health and maximizing yields. As per the Agricultural and Biological Engineering Society, utilizing high flow pumps in irrigation can increase water efficiency by over 20%, benefiting farmers in both yields and resource management.

Tip: Regular maintenance of hydraulic systems can significantly extend pump life and enhance performance, ensuring a sustained return on investment.

Related Posts

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

How to Choose the Right Hydraulic Pump for Your Industrial Needs

-

Exploring Market Trends for High Flow Pumps at the 2025 China Import and Export Fair

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications