In the ever-evolving landscape of industrial applications, the demand for efficient and reliable pumping solutions has surged, positioning the Stainless Steel Centrifugal Pump as a critical component across various sectors. According to a recent market report by Grand View Research, the global centrifugal pump market is projected to reach $42.5 billion by 2025, with stainless steel pumps being a significant contributor due to their durability and corrosion resistance. Industries such as water treatment, chemicals, oil and gas, food and beverage, and pharmaceuticals heavily rely on stainless steel centrifugal pumps for their ability to handle aggressive fluids while maintaining hygiene standards. This blog will explore the top five applications of the best stainless steel centrifugal pumps and highlight why they stand at the forefront of manufacturing excellence in factories that rank among the best globally.

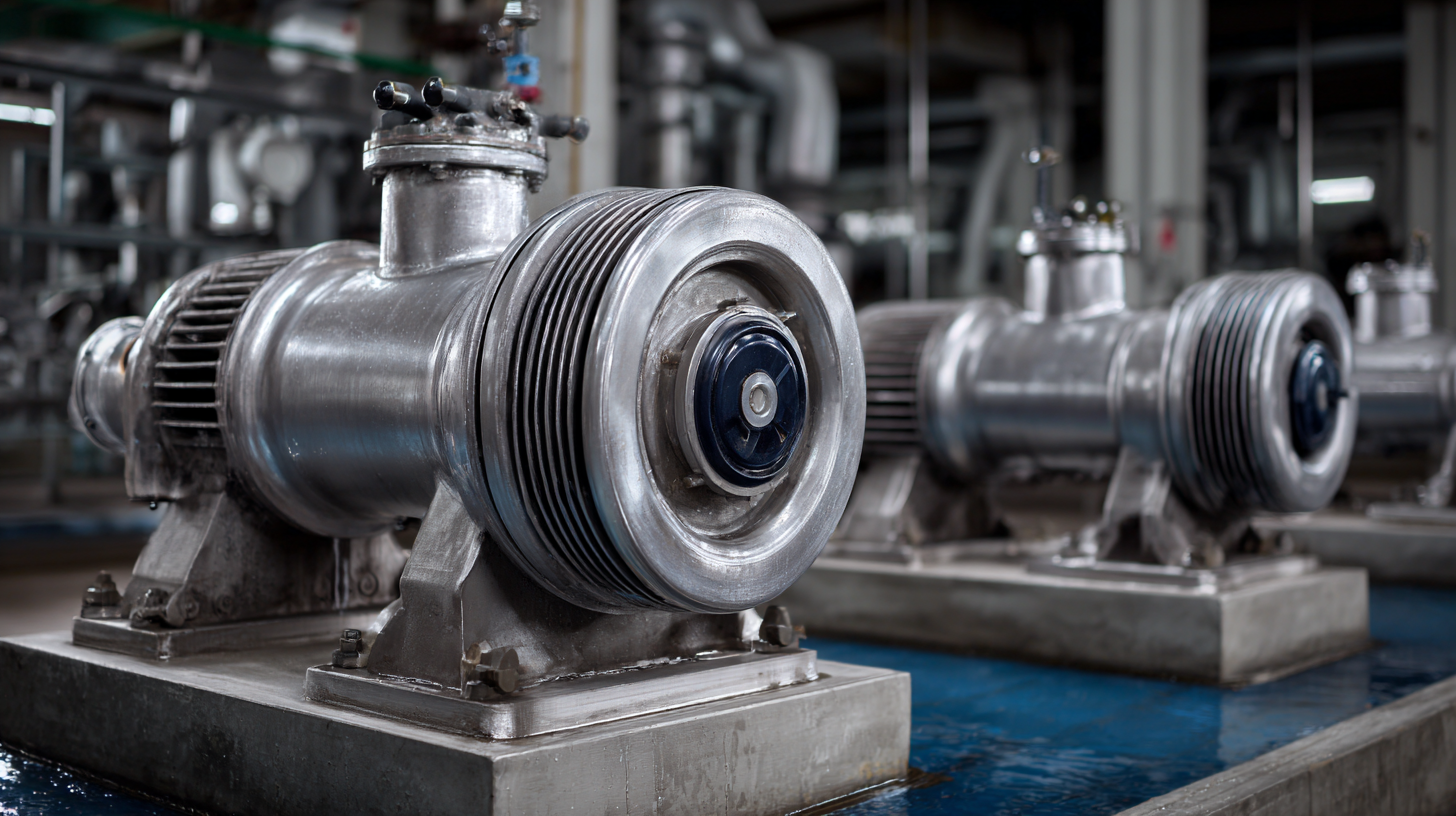

Stainless steel centrifugal pumps have become essential components in various industrial applications due to their remarkable durability and efficiency. One of the primary benefits of these pumps is their excellent resistance to corrosion, making them ideal for handling aggressive fluids in industries such as chemical processing and food production. Their construction allows them to withstand harsh environments while maintaining optimal performance, thereby reducing maintenance costs and downtime.

In addition to their corrosion resistance, stainless steel centrifugal pumps offer high efficiency and reliability. The smooth surface of stainless steel ensures minimal friction loss, leading to improved energy efficiency during operation. This translates to lower operational costs, which is especially critical in industries where energy expenditures can be significant. Furthermore, the versatility of these pumps enables them to be used in a wide range of applications, from water treatment to pharmaceutical manufacturing, showcasing their adaptability and effectiveness across different sectors.

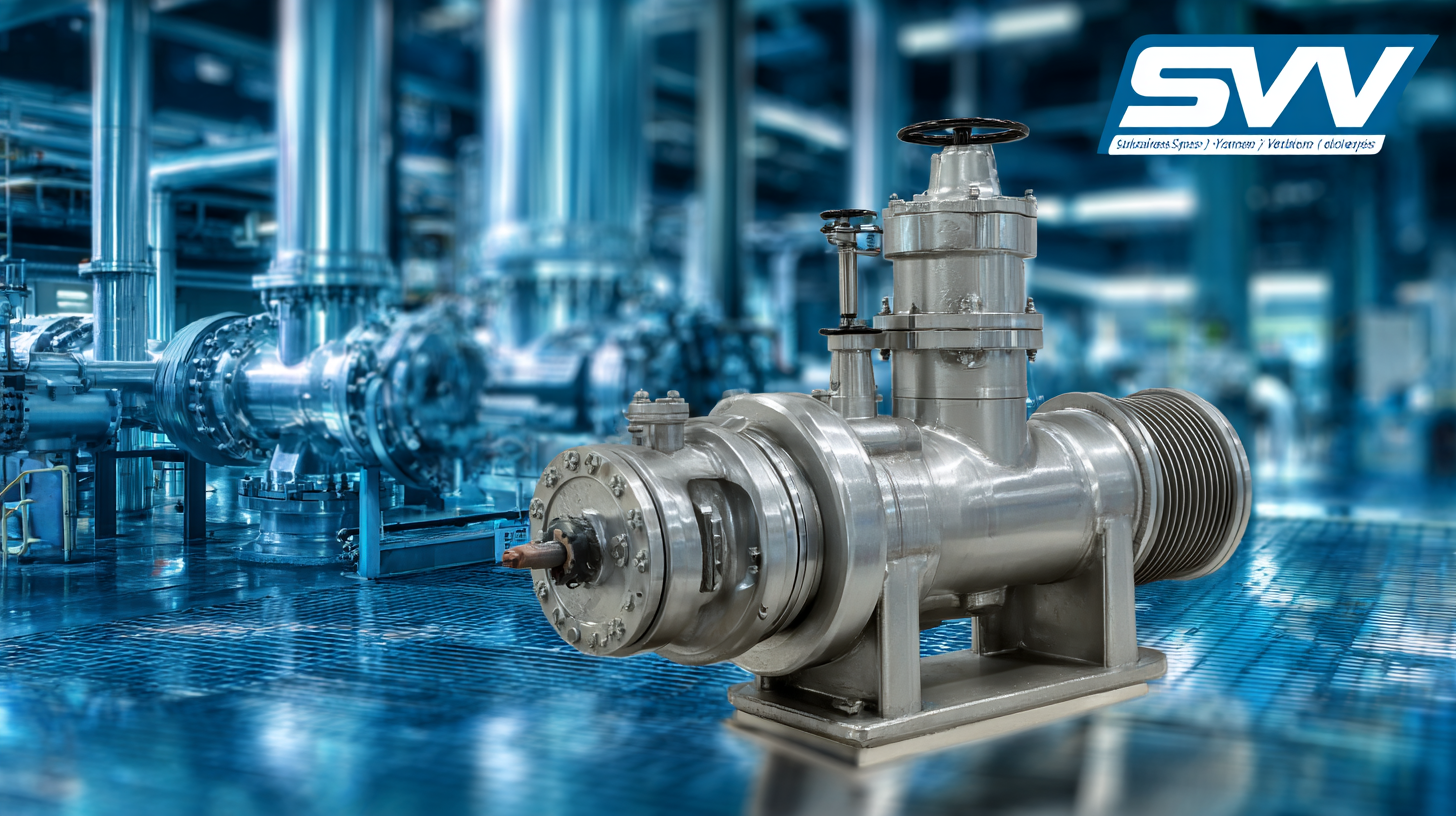

When selecting a quality manufacturer for stainless steel centrifugal pumps, several critical factors must be considered to ensure optimal performance and reliability. One of the primary aspects is the manufacturer’s experience and reputation in the industry. According to a report by Research and Markets, the global market for centrifugal pumps is projected to reach $41 billion by 2027, highlighting the increasing demand for high-quality equipment. Established manufacturers often have a proven track record and are more likely to produce durable pumps that meet strict industry standards.

Another essential factor is the quality of materials used in the manufacturing process. Stainless steel, known for its corrosion resistance and strength, is crucial for pumps used in industries such as food and beverage, pharmaceuticals, and wastewater management. A recent study from the International Journal of Machinery and Mechanical Engineering emphasizes the role of material selection in enhancing the lifespan and efficiency of pumps. Moreover, prospective buyers should evaluate the manufacturer’s adherence to certification standards like ISO 9001, which ensures that products meet consistent quality requirements, ultimately influencing the pump's reliability and operational longevity.

Stainless steel centrifugal pumps are indispensable in a variety of industries due to their durability, corrosion resistance, and efficiency. One of the top sectors utilizing these pumps is the food and beverage industry. Their ability to handle liquids without contamination makes them ideal for transporting ingredients and processing beverages, ensuring product safety and quality.

Another significant industry reaping the benefits of stainless steel centrifugal pumps is the pharmaceutical sector. These pumps are critical in the manufacturing of medications, where precision and hygiene are paramount. The smooth operation and ease of cleaning help maintain strict regulatory standards, ensuring that production processes remain compliant with health guidelines.

**Tips:** When selecting a stainless steel centrifugal pump, always consider the specific requirements of your application, including flow rate and pressure range. Regular maintenance is essential to prevent wear and tear, ensuring longevity and optimal performance. Additionally, it’s wise to assess the compatibility of the pump materials with the liquids being handled to avoid any potential chemical reactions.

When it comes to pump manufacturing, the choice of material significantly influences performance, durability, and cost-effectiveness.

Stainless steel is widely favored due to its exceptional resistance to corrosion and wear, making it an ideal candidate for demanding environments like chemical processing and food production.

Unlike plastic or other metals, stainless steel can withstand high temperatures and pressures, ensuring longevity and reliability in critical applications.

This durability translates to reduced maintenance costs and fewer replacement cycles, benefiting industries that require continuous operation.

Stainless steel is widely favored due to its exceptional resistance to corrosion and wear, making it an ideal candidate for demanding environments like chemical processing and food production.

Unlike plastic or other metals, stainless steel can withstand high temperatures and pressures, ensuring longevity and reliability in critical applications.

This durability translates to reduced maintenance costs and fewer replacement cycles, benefiting industries that require continuous operation.

On the other hand, materials such as rubber and aluminum may offer advantages in specific scenarios, such as lower initial costs or lightweight construction.

Rubber pumps excel in environments where flexibility is essential, while aluminum is often chosen for portability.

However, these materials may not provide the same level of protection against corrosive substances or extreme conditions, leading to potential failures that could interrupt operations.

Therefore, while stainless steel may come at a higher price point, its superior performance in terms of strength and resilience justifies the investment, particularly for applications demanding the highest standards of hygiene and safety.

When it comes to maintaining the longevity of stainless steel centrifugal pumps, a proactive approach to upkeep can make a significant difference in performance and durability. Regular inspections are essential; checking for wear and tear, leaks, and ensuring proper alignment can prevent minor issues from escalating into major problems. In addition, it is vital to keep the pump clean and free of debris, especially in applications where particles may enter the system. This not only enhances efficiency but also extends the service life of the equipment.

Another critical aspect of maintenance is monitoring the operational conditions of the pump. Ensuring that the pump operates within its designed parameters—such as flow rate, pressure, and temperature—will help minimize stress on the components. Implementing a scheduled maintenance routine, including lubrication of moving parts and replacement of seals and bearings, can further enhance the pump’s reliability. By adhering to these tips, industries relying on stainless steel centrifugal pumps can ensure optimal performance and longevity, ultimately leading to increased productivity and reduced operational costs.

Copyright © 2023 TUF Pump Industry (Jiangsu) Co., Ltd. - Stainless Steel Centrifugal Pump, Chemical Pump, Metering Pump - All Rights Reserved.