Blog

- Home

- Blog

How to Choose the Right High Pressure Pump for Your Industrial Needs

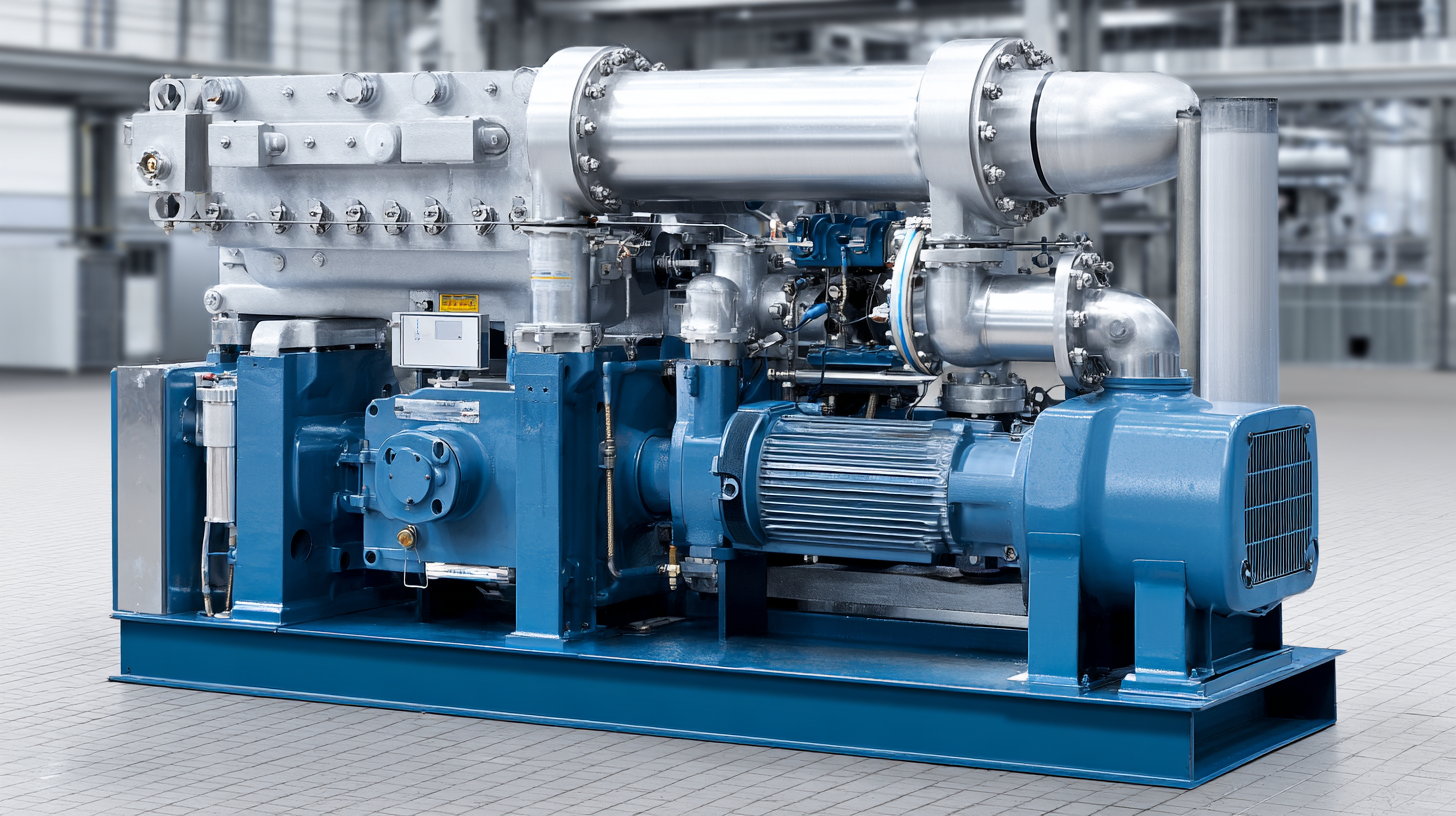

Choosing the right high pressure pump for your industrial needs is a critical decision that can significantly impact the efficiency and effectiveness of your operations. High pressure pumps are essential in a variety of applications, such as water jet cutting, surface preparation, and even in certain chemical processes. The appropriate selection involves several factors, including the type of fluid being pumped, the required pressure and flow rate, and the specific operating conditions. Understanding these requirements is vital to ensure optimal performance and longevity of the pump.

Additionally, various types of high pressure pumps, from diaphragm to piston pumps, offer distinct advantages depending on the application. In this guide, we will explore key considerations and tips for selecting the best high pressure pump tailored to your industrial applications, ensuring you make an informed and strategic investment.

Understanding Your Industrial Applications: Key Parameters for High Pressure Pumps

When selecting a high pressure pump for industrial applications, understanding key parameters is crucial. First and foremost, assess the specific requirements of your operation, such as flow rate and pressure output. These factors vary significantly depending on the task at hand, whether it's cleaning, material transport, or chemical injection. Matching the pump's characteristics to the application's demands ensures optimal performance and efficiency.

Additionally, consider the fluid type that will be handled. Different fluids, such as water, chemicals, or abrasive materials, may require specialized pump designs and materials to prevent wear and corrosion. Pump construction, including pump head, impeller design, and casing materials, plays an essential role in durability and suitability for your specific medium. Moreover, energy efficiency is increasingly important in industrial settings, so evaluating the pump’s operational costs alongside its performance capabilities can lead to more sustainable choices.

Evaluating Pump Performance Metrics: Flow Rate, Pressure, and Efficiency Factors

When selecting a high pressure pump for industrial applications, evaluating performance metrics such as flow rate, pressure, and efficiency is crucial. The flow rate, typically measured in gallons per minute (GPM) or liters per second (L/s), indicates how much fluid the pump can transfer within a specific timeframe. According to a 2021 market analysis by Research and Markets, pumps that offer adjustable flow rates can enhance operational flexibility, allowing industries to adapt to varying demands, especially in sectors like oil and gas, which often require changes in fluid dynamics.

Pressure is another vital metric that defines a pump’s capability. It is usually measured in pounds per square inch (PSI) or bar. High pressure pumps are often required in applications such as water jet cutting and hydraulic fracturing. The Global High Pressure Pump Market report indicates that pumps capable of achieving pressures above 600 PSI are in high demand for these applications, which require both durability and reliability under extreme conditions. Lastly, efficiency factors—often calculated as the ratio of hydraulic power output to mechanical power input—can significantly impact operating costs. The Hydraulic Institute suggests that improving pump efficiency by just 1% can lead to substantial energy savings, emphasizing the importance of selecting a pump that meets both performance and energy standards.

Selecting the Right Material: Corrosion Resistance and Durability in Pump Design

When selecting a high pressure pump for industrial applications, the choice of materials is paramount, particularly concerning corrosion resistance and durability. According to a study by the Pumps and Systems magazine, approximately 80% of pump failures are attributed to corrosion-related issues. Thus, choosing the right material can significantly enhance the longevity and reliability of the pump. Common materials include stainless steel, duplex stainless steel, and various high-performance polymers, each offering varying degrees of resistance to corrosive environments. For instance, duplex stainless steel provides a high strength-to-weight ratio and excellent resistance to pitting and crevice corrosion, making it suitable for applications in the oil and gas industry, where exposure to harsh chemicals is common.

Furthermore, industry reports indicate that over 60% of companies experience unplanned downtime due to pump failures, leading to significant losses. Selecting durable materials not only reduces the likelihood of pump failures but also minimizes maintenance costs. For example, pumps manufactured with high-performance thermoplastics can withstand aggressive chemicals and high pressures, resulting in extended service life. As industries continue to evolve and adopt more stringent environmental regulations, investing in high-quality pump materials that prioritize both corrosion resistance and durability is becoming increasingly crucial for operational efficiency and cost-effectiveness.

Considerations for Pump Size and Power: Balancing Output and Energy Consumption

When selecting a high-pressure pump for industrial applications, it is essential to carefully consider both the pump size and power requirements to strike an optimal balance between output and energy consumption. The advancements in hybrid renewable energy systems, particularly for water pumping applications, highlight the increasing importance of efficiency in pump design. By integrating renewable energy sources, these systems not only enhance performance but also significantly reduce operational costs, ultimately leading to more sustainable industrial practices.

In addition to energy efficiency, the size of the pump should align with the specific requirements of the application to avoid excessive energy use. Larger pumps may provide higher outputs, but they can also lead to increased energy consumption. Research indicates that transitioning to heat pumps could likewise influence energy demand patterns in the power sector, signaling that careful consideration of both pump size and energy source can help mitigate fossil fuel reliance while supporting a move toward net-zero energy goals. Understanding these dynamics can guide industrial operators in making informed decisions that contribute both to operational efficiency and environmental sustainability.

Maintenance and Reliability: Ensuring Longevity in High Pressure Pump Operations

When it comes to high pressure pumps, maintenance and reliability are paramount to ensuring longevity in operations. Regular upkeep not only extends the life of your pump but also prevents unexpected breakdowns that can disrupt industrial processes. Implementing a robust maintenance schedule is essential; this should include frequent inspections, component replacements, and proper lubrication. It's also important to monitor any vibrations or unusual noises during operation, as these can indicate underlying issues that need immediate attention.

**Tips:** Keep a log of maintenance activities and any anomalies observed during pump operation. This historical data will help in predicting future maintenance needs and identifying recurring issues.

In addition to routine maintenance, investing in quality parts and knowledgeable technicians can greatly enhance the reliability of your high pressure pump. Using OEM (Original Equipment Manufacturer) parts ensures compatibility and durability. Training your staff on proper operating techniques is equally important, as incorrect usage can lead to premature wear.

**Tips:** Create a training program that includes regular updates on best practices and troubleshooting methods to boost your team's competence when handling pump-related challenges.

How to Choose the Right High Pressure Pump for Your Industrial Needs - Maintenance and Reliability: Ensuring Longevity in High Pressure Pump Operations

| Pump Type | Pressure Range (psi) | Flow Rate (GPM) | Material | Maintenance Frequency (Months) | Expected Lifespan (Years) | Reliability Rating (1-5) |

|---|---|---|---|---|---|---|

| Centrifugal Pump | 100 - 2000 | 10 - 500 | Stainless Steel | 6 | 5 | 4 |

| Diaphragm Pump | 50 - 1500 | 2 - 200 | Polypropylene | 3 | 7 | 5 |

| Positive Displacement Pump | 10 - 3000 | 1 - 150 | Cast Iron | 12 | 10 | 4 |

| Gear Pump | 30 - 2000 | 0.5 - 100 | Aluminum | 6 | 8 | 3 |

Related Posts

-

7 Best Industrial Pumps You Should Consider for Your Next Project

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

How to Choose the Right Hydraulic Pump for Your Industrial Needs

-

5 Essential Tips for Sourcing the Best Pump Water Solutions Globally

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications