Blog

- Home

- Blog

How to Choose the Right Hydraulic Pump for Your Industrial Needs

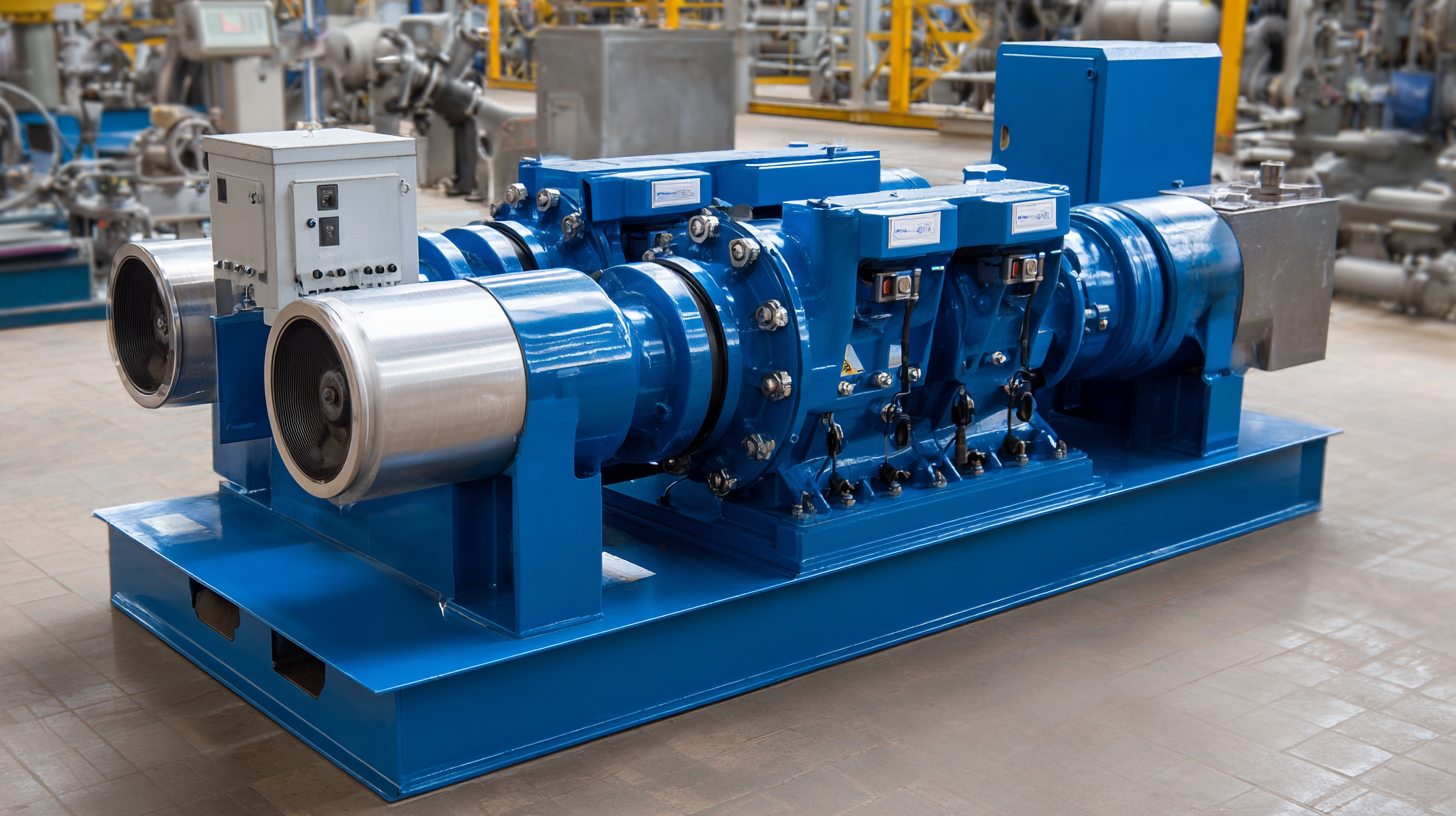

In the ever-evolving landscape of industrial machinery, choosing the right hydraulic pump is crucial for ensuring optimal performance and productivity. With the global hydraulic pump market projected to reach $30 billion by 2024, driven by advancements in automation and increased demand for efficient fluid control systems, making an informed decision has never been more imperative. A hydraulic pump (Pump Hydraulic) not only influences operational efficiency but also impacts energy consumption and maintenance costs. Selecting the appropriate type—whether gear, vane, or piston—depends on various factors such as flow rate, pressure requirements, and application-specific parameters. According to a recent industry report, about 70% of hydraulic system failures stem from improper pump selection, underscoring the importance of thorough analysis before investment. By understanding the essential criteria for hydraulic pump selection, businesses can enhance their operational efficiency and safeguard their investments in machinery.

Understanding the Different Types of Hydraulic Pumps Available for Industries

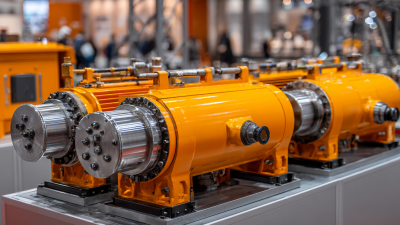

When selecting a hydraulic pump for industrial applications, it's essential to understand the various types available, each designed to meet specific operational demands. The two primary categories of hydraulic pumps are positive displacement pumps and dynamics pumps. Positive displacement pumps, including gear, vane, and piston pumps, work by trapping a fixed amount of fluid and forcing it into the system. They are known for their efficiency in generating high pressure and for maintaining a steady flow rate, making them suitable for applications requiring precise fluid control.

When selecting a hydraulic pump for industrial applications, it's essential to understand the various types available, each designed to meet specific operational demands. The two primary categories of hydraulic pumps are positive displacement pumps and dynamics pumps. Positive displacement pumps, including gear, vane, and piston pumps, work by trapping a fixed amount of fluid and forcing it into the system. They are known for their efficiency in generating high pressure and for maintaining a steady flow rate, making them suitable for applications requiring precise fluid control.

On the other hand, dynamic pumps, such as centrifugal pumps, rely on rotational energy to move fluids. These pumps are best suited for applications where a large volume of fluid needs to be transported at lower pressures. While they are effective in providing continuous flow, they may not handle high pressure as efficiently as positive displacement pumps. Understanding the operational requirements, including pressure needs, flow rate, and fluid characteristics, is crucial in choosing the right hydraulic pump for your industrial needs.

Evaluating Performance Parameters: Pressure, Flow Rate, and Efficiency

When selecting a hydraulic pump for industrial applications, it is crucial to evaluate key performance parameters such as pressure, flow rate, and efficiency. Pressure capacity is often the first consideration, as it dictates the pump's ability to perform tasks against resistance. Industrial applications may require pumps capable of generating high pressure to effectively handle loads, especially in heavy machinery operations. Thus, understanding the system's maximum pressure requirements is essential to avoid pump failure or inefficiencies.

In addition to pressure, the flow rate plays a significant role in determining the pump's suitability for your needs. Flow rate refers to the volume of fluid the pump can move per unit of time, which directly affects the speed and effectiveness of the hydraulic system. Ensuring that the pump can provide the required flow rate under specific operating conditions is vital for maintaining consistent performance. Lastly, evaluating the efficiency of the hydraulic pump is critical. A more efficient pump will consume less energy, leading to lower operational costs and reduced environmental impact. By carefully analyzing these parameters, businesses can make informed decisions and choose the right hydraulic pump for their industrial needs.

Hydraulic Pump Performance Evaluation

This chart illustrates the evaluation of hydraulic pump performance based on key parameters: Pressure (in PSI), Flow Rate (in GPM), and Efficiency (%). The data represents a range of values commonly found in industrial hydraulic pumps.

Assessing Compatibility with Your Existing Hydraulic System and Components

When selecting a hydraulic pump for industrial applications, assessing compatibility with your existing hydraulic system and components is crucial. A study from the Hydraulic Institute indicates that nearly 30% of hydraulic system failures are due to mismatched components. This highlights the importance of ensuring that the pump you choose aligns with the specifications of your current system, including flow rates, pressure ratings, and physical dimensions.

Consider the operating environment and the specific demands of your application. For instance, if your system presently utilizes gear pumps operating at 2500 psi, introducing a pump that exceeds these ratings could jeopardize the entire system. Additionally, cross-compatibility with hydraulic fluid types and transmission methods is essential; using incompatible fluid can lead to reduced efficiency and equipment degradation. According to the National Fluid Power Association, effective system integration can enhance hydraulic efficiency by up to 25%, leading to improved productivity and reduced operational costs. Therefore, taking the time to evaluate your existing system ensures you make informed decisions in hydraulic pump selection, optimizing performance and longevity.

Identifying Key Application Requirements for Optimal Pump Selection

When selecting a hydraulic pump for industrial applications, understanding the specific requirements of the application is crucial. Factors such as flow rate, pressure, and fluid characteristics must be carefully considered. For instance, in a study of water distribution networks (WDNs), the integration of hydraulic pumps as turbines has shown promise in enhancing energy efficiency while contributing to sustainable practices in small hydropower applications. This approach underscores the importance of identifying not only capacity requirements but also the potential for energy recovery in pump selection.

When selecting a hydraulic pump for industrial applications, understanding the specific requirements of the application is crucial. Factors such as flow rate, pressure, and fluid characteristics must be carefully considered. For instance, in a study of water distribution networks (WDNs), the integration of hydraulic pumps as turbines has shown promise in enhancing energy efficiency while contributing to sustainable practices in small hydropower applications. This approach underscores the importance of identifying not only capacity requirements but also the potential for energy recovery in pump selection.

Additionally, advancements in diagnostic technologies, such as the application of one-way analysis of variance (ANOVA), have illustrated how critical it is to assess pump performance through operational data. By ranking diagnostic signals, engineers can pinpoint essential features that indicate the operational health of displacement pumps, improving reliability and reducing maintenance costs. The analysis of sensor data from large-scale deployments, such as over 1,000 heat pumps in residential buildings, further emphasizes the importance of gathering empirical data to inform pump selection—leading to solutions that not only meet operational needs but also optimize energy use and performance over time.

Budget Considerations: Cost vs. Quality in Hydraulic Pump Purchasing Decisions

When selecting a hydraulic pump for industrial applications, budget considerations play a pivotal role in the decision-making process. A report from MarketsandMarkets indicates that the global hydraulic pump market is expected to grow from $9.0 billion in 2021 to $12.1 billion by 2026, highlighting a significant investment trend in hydraulic equipment. This growth underscores the need for businesses to carefully evaluate their spending, balancing cost with the quality of hydraulic pumps. Investing in higher-quality hydraulic pumps may require a higher initial outlay, but companies could see long-term savings through reduced maintenance costs and enhanced durability.

Moreover, the distinction between cost and quality is critical. While cheaper pumps may seem appealing, they often compromise on efficiency and longevity. According to a study by Grand View Research, low-quality hydraulic pumps can lead to 15-25% more operational downtime, which can be detrimental in high-stakes industrial settings. Therefore, it's essential to analyze the total cost of ownership rather than solely focusing on the upfront price. By factoring in these considerations, companies can make informed decisions that align their budgetary constraints with their operational needs, ultimately leading to more sustainable and effective hydraulic systems.

How to Choose the Right Hydraulic Pump for Your Industrial Needs - Budget Considerations: Cost vs. Quality in Hydraulic Pump Purchasing Decisions

| Pump Type | Price Range (USD) | Typical Uses | Quality Rating (1-5) | Expected Lifespan (Years) |

|---|---|---|---|---|

| Gear Pump | $200 - $800 | Construction, Agriculture | 4 | 10-15 |

| Piston Pump | $500 - $2000 | Mining, Manufacturing | 5 | 15-25 |

| Vane Pump | $300 - $1200 | Automotive, HVAC | 3 | 8-12 |

| diaphragm Pump | $400 - $1500 | Chemical processing, Food industry | 4 | 10-20 |

Related Posts

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

Ultimate Guide to Selecting the Right Industrial Dosing Pump for Your Needs

-

How to Choose the Right Dosing Pump for Your Industrial Needs Based on Flow Rates and Chemical Compatibility