Blog

- Home

- Blog

How to Choose the Right Dosing Pump for Your Industrial Needs Based on Flow Rates and Chemical Compatibility

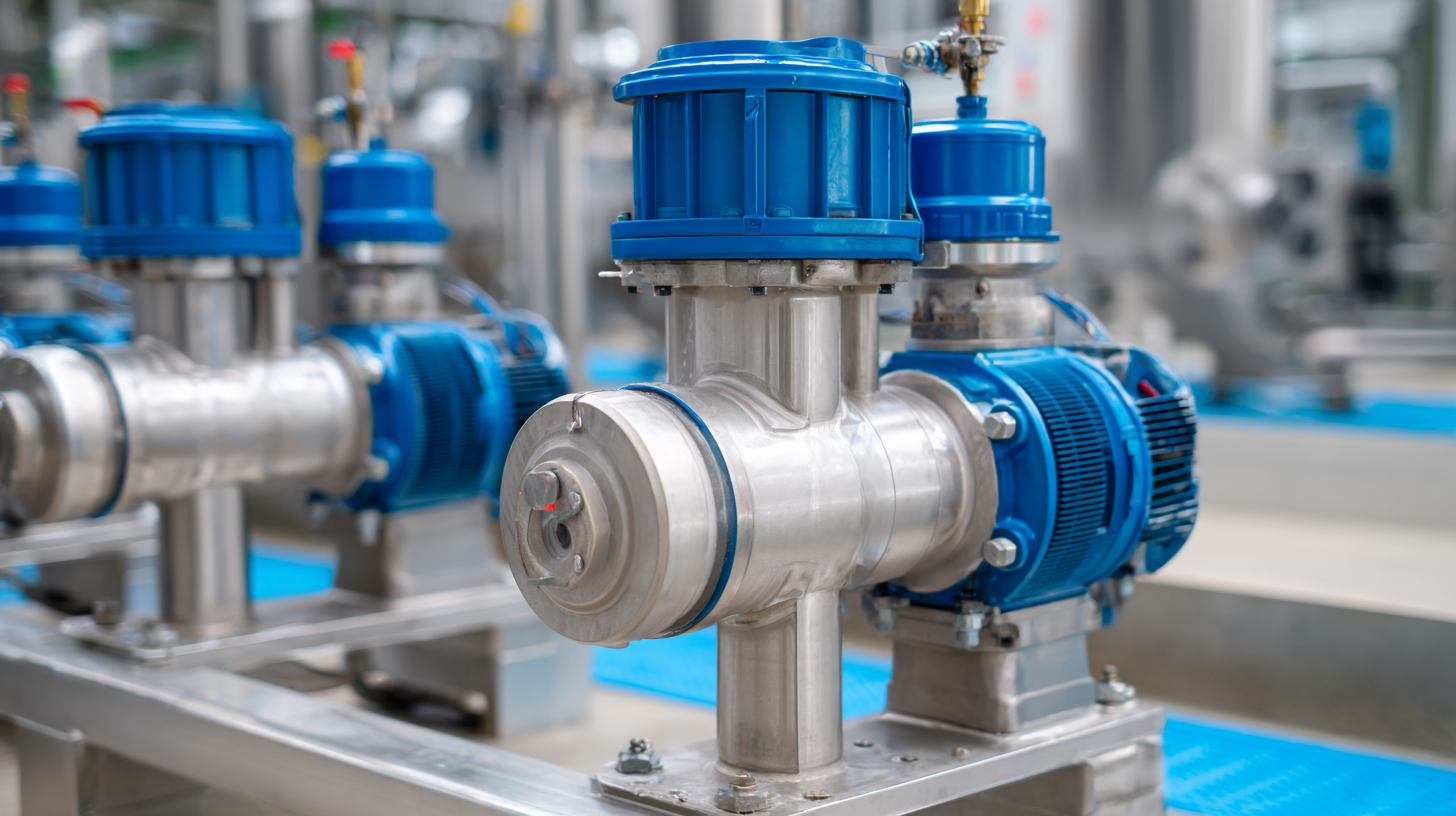

When it comes to optimizing industrial processes, choosing the right dosing pumps is crucial for achieving efficient and effective results. With a multitude of options available, industries often find themselves overwhelmed by the decision-making process.

Factors such as flow rates and chemical compatibility play significant roles in determining which pump will best meet specific operational needs. Understanding these variables is essential for ensuring that the dosing pumps not only function properly but also enhance productivity and maintain safety standards.

In this blog, we will provide you with valuable tips on how to assess your requirements and select the ideal dosing pump tailored to your facility's unique demands. By focusing on flow rates and chemical interactions, we aim to equip you with the knowledge necessary for making informed choices in your industrial applications.

Factors Influencing Flow Rate Selection for Dosing Pumps in Industrial Applications

When selecting a dosing pump for industrial applications, understanding the factors that influence flow rate selection is critical to ensuring optimal performance and efficiency. According to the Fluid Control International's 2022 report, nearly 70% of operational failures in industrial dosing systems can be traced back to incorrect flow rate specifications. Flow rates must align with the specific requirements of the process, including the type of chemical being handled, the desired accuracy, and the overall system design.

Furthermore, application-specific considerations such as pressure, temperature, and the physical layout of the installation must also be factored into flow rate selection. A study by the Association of Pumps Manufacturers indicated that nearly 55% of businesses overlook these parameters, leading to less efficient dosing processes. By conducting a thorough analysis of these influencing factors, industries can enhance the reliability and effectiveness of their dosing systems, ultimately leading to improved productivity and reduced operational costs.

Understanding Chemical Compatibility: Key Standards and Guidelines for Dosing Pumps

When selecting a dosing pump for industrial applications, understanding chemical compatibility is essential to ensure both efficiency and safety. Dosing pumps frequently handle a wide range of chemicals, and improper material selection can result in pump failure or leakage. According to a report by the Chemical Engineering & Equipment Journal, approximately 15% of all pump failures in industrial settings stem from compatibility issues with the substances being pumped. This highlights the necessity for thorough evaluations based on specific chemical properties such as pH, temperature, and viscosity.

Key standards and guidelines should be followed to ascertain chemical compatibility. Manufacturers often provide compatibility charts that categorize materials based on how well they resist degradation when in contact with various chemicals. The American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set forth criteria that help in the selection of pump materials. A study from the Fluid Pumping Association indicates that pumps made from materials such as stainless steel and certain plastics can withstand a wide array of chemical interactions, thus enhancing operational reliability. Ultimately, understanding and applying these standards is crucial for optimizing pump performance and prolonging service life.

How to Choose the Right Dosing Pump for Your Industrial Needs Based on Flow Rates and Chemical Compatibility

| Dosing Pump Type | Maximum Flow Rate (L/hr) | Chemical Compatibility | Pressure Range (bar) | Common Applications |

|---|---|---|---|---|

| Diaphragm Pump | 50 | Acids, Bases | 0-10 | Water Treatment, Chemical Processing |

| Piston Pump | 200 | Solvents, Viscous Fluids | 0-15 | Oil & Gas, Food & Beverage |

| Peristaltic Pump | 120 | Biological Fluids, Suspensions | 0-2 | Pharmaceuticals, Waste Water Treatment |

| Gear Pump | 80 | Oils, Non-Aqueous Solutions | 0-10 | Chemical Transfer, Lubrication |

Comparative Analysis: Types of Dosing Pumps and Their Flow Rate Capacities

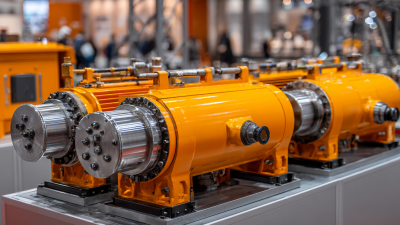

When selecting the right dosing pump for industrial applications, understanding the flow rate capacities of different types is crucial. Dosing pumps are typically categorized into three main types: diaphragm pumps, peristaltic pumps, and piston pumps, each with distinct flow rate capabilities. According to a report by Research and Markets, diaphragm dosing pumps can handle flow rates from as low as 0.1 L/h to over 1000 L/h, making them ideal for precise chemical dosing in applications like water treatment and pharmaceutical manufacturing. Their ability to maintain constant flow under varying pressures makes them a reliable choice for consistent chemical delivery.

Peristaltic pumps, on the other hand, offer flow rates ranging from 0.1 L/h up to 1500 L/h. These pumps are particularly beneficial for applications requiring the transportation of viscous or shear-sensitive fluids. A technical paper by the American Chemical Society highlights their compatibility with a wide array of chemicals, making them a versatile option for various industrial processes. Meanwhile, piston pumps are known for their high pressure and flow capabilities, with rates exceeding 3000 L/h, suitable for industries such as oil and gas. Understanding these distinctions is vital to ensuring optimal performance and chemical compatibility in your specific industrial needs.

Industry Case Studies: Effective Dosing Pump Utilization in Various Sectors

In various industrial sectors, the effective utilization of dosing pumps is critical to achieving precise chemical mixing and process efficiency. For example, in the water treatment industry, dosing pumps are used to deliver accurate amounts of chlorine or other disinfectants needed to ensure safe drinking water. Case studies show that by fine-tuning flow rates and selecting pumps specifically designed for chemical compatibility, facilities can reduce chemical waste and enhance water quality.

Similarly, in the food processing sector, dosing pumps play a vital role in the addition of flavors, preservatives, and other additives. A notable case involved a large beverage manufacturer that implemented a new dosing pump system, allowing for real-time adjustments to flow rates. This flexibility not only improved product consistency but also led to a significant reduction in production downtime. By examining these applications, it's evident that understanding flow rates and chemical compatibility is crucial for optimizing dosing pump performance in diverse industrial environments.

Cost-Benefit Analysis: The Long-Term Impacts of Choosing the Right Dosing Pump

When choosing a dosing pump for industrial applications, it's essential to consider not just the upfront cost but also the long-term implications of your choice. A well-selected dosing pump can enhance efficiency and reduce operating costs over time. By analyzing the cost-benefit aspect, you can make a more informed decision that aligns with your operational needs and budget constraints.

**Tip:** Always account for the pump's maintenance and replacement costs in your analysis. A more expensive dosing pump with high efficiency and durability may prove to be a better investment than a cheaper alternative that requires frequent repairs.

Additionally, consider the pump's energy consumption and how it impacts your overall operational costs. Selecting a pump designed for lower flow rates can lead to significant savings in energy use, thus offering a substantial return on investment.

**Tip:** Evaluate the chemical compatibility of the pump materials. Properly matching the pump with the chemicals being handled not only extends the lifespan of the equipment but also prevents costly leaks and downtime, safeguarding your production line’s efficiency.

Cost-Benefit Analysis of Dosing Pumps Based on Flow Rates and Chemical Compatibility

Related Posts

-

7 Best Dosing Pumps for Precision Chemical Dispensing

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

-

Unlocking Efficiency: The Significant Advantages of Plunger Metering Pumps in Process Industries

-

Ultimate Guide to Selecting the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

Understanding Common Issues Faced by Users of Plunger Pumps