Blog

- Home

- Blog

Understanding the Efficiency and Applications of Plunger Metering Pumps in Industrial Settings

In the realm of industrial fluid management, the Plunger Metering Pump stands out as a pivotal solution known for its precision and reliability. As industries increasingly demand more efficient and controlled processes, these pumps have emerged as essential components for a wide range of applications, from chemical processing to water treatment. Understanding the intricacies of Plunger Metering Pumps not only highlights their operational efficiency but also sheds light on their versatility in various industrial settings.

This article delves into the "Top 5" benefits and applications of Plunger Metering Pumps, showcasing how they optimize fluid delivery with accuracy and facilitate seamless integration into existing systems. By examining key performance metrics and real-world implementations, we aim to provide insights that empower industrial operators to make informed decisions regarding their fluid metering needs. With advancements in technology and design, these pumps continue to evolve, making them integral to the efficient and sustainable practices within modern industries.

The Role of Plunger Metering Pumps in Modern Industrial Applications

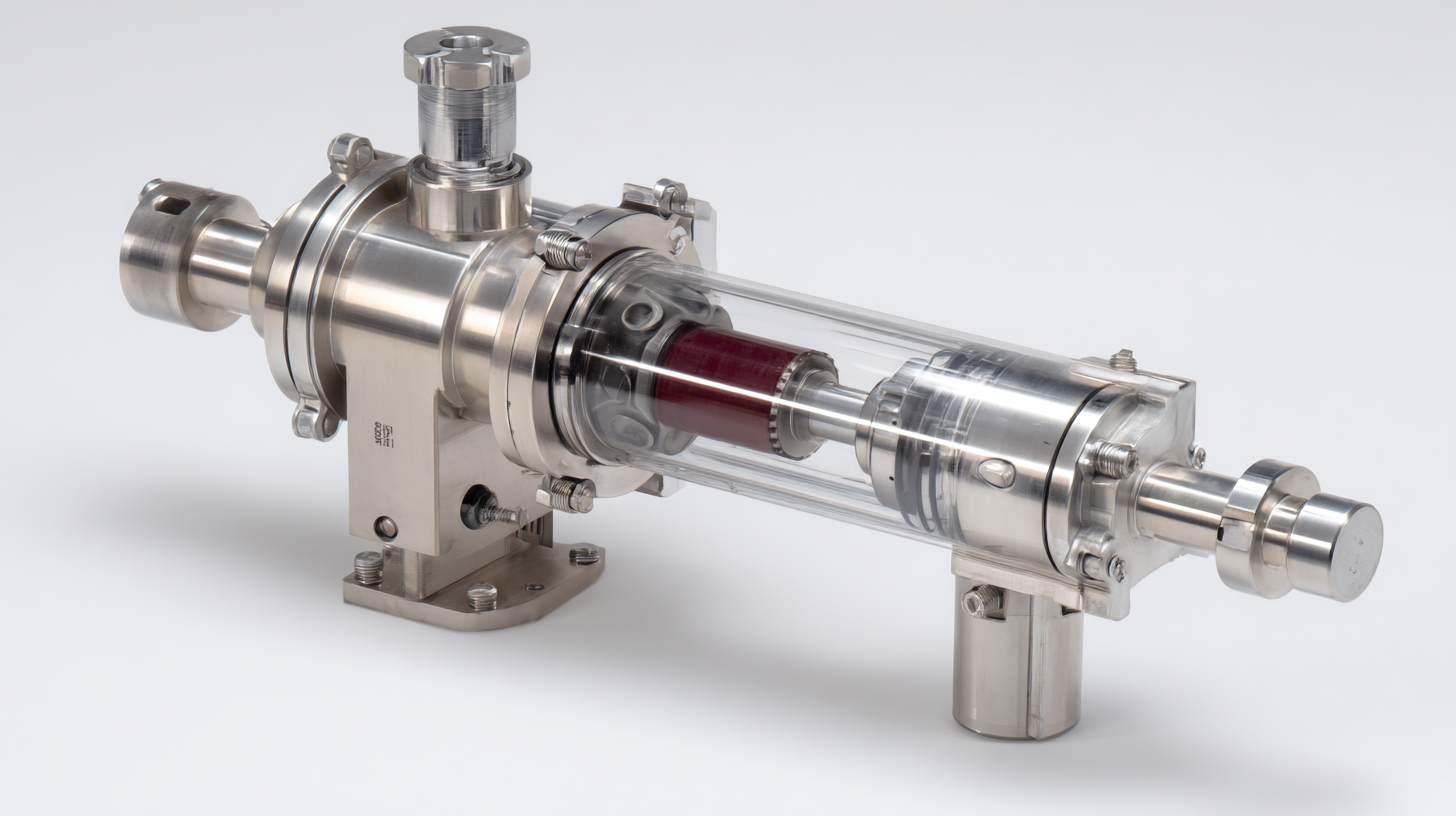

Plunger metering pumps

play a crucial role in modern industrial applications, particularly in processes where precision and consistency are paramount. According to a report by Grand View Research, the global demand for metering pumps is expected to reach USD 5.61 billion by 2025, driven by increased automation in manufacturing and stringent environmental regulations. These pumps are designed to deliver accurate fluid measurements, making them indispensable in industries such as chemical processing, water treatment, and pharmaceuticals.

The efficiency of plunger metering pumps lies in their ability to handle varying viscosities and flow rates without sacrificing performance. Industrial users have increasingly recognized this versatility; a study from Research and Markets estimates that the chemical sector will witness the largest growth, constituting over 40% of the market share by 2026. The robust construction and reliability of plunger metering pumps ensure that they can withstand harsh operating conditions, while their ability to maintain a steady flow of fluids contributes significantly to operational efficiency and product quality.

Efficiency Metrics: Analyzing Performance and Cost-Effectiveness

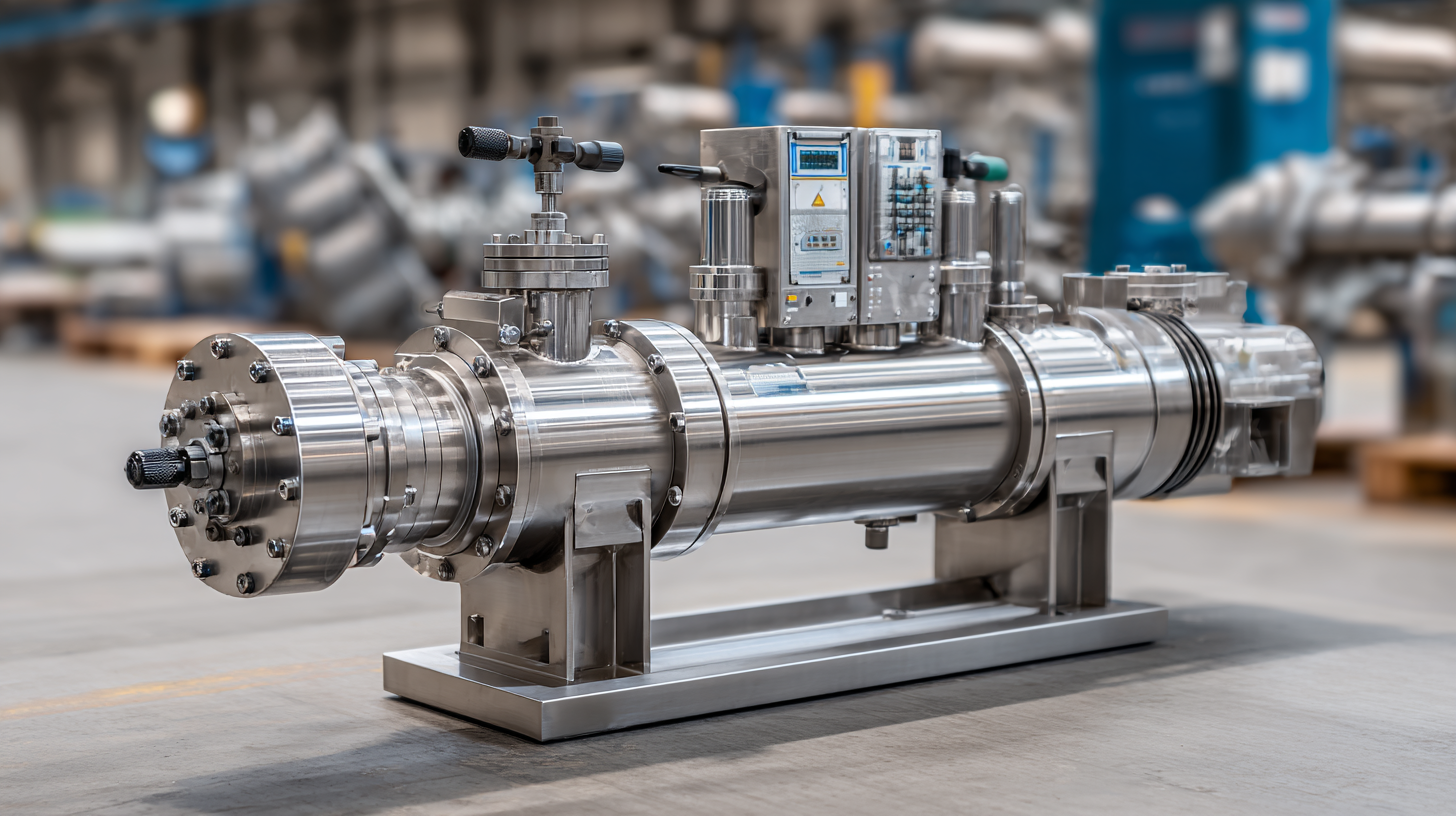

Efficiency metrics play a crucial role in evaluating the performance and cost-effectiveness of plunger metering pumps within industrial settings. These pumps are often chosen for their ability to handle high pressure and deliver precise flow rates, making them ideal for applications such as chemical dosing, water treatment, and oil refining. Key performance indicators include flow rate accuracy, energy consumption, maintenance frequency, and downtime. By analyzing these metrics, industries can determine the optimal pump design and operating conditions to maximize efficiency.

Efficiency metrics play a crucial role in evaluating the performance and cost-effectiveness of plunger metering pumps within industrial settings. These pumps are often chosen for their ability to handle high pressure and deliver precise flow rates, making them ideal for applications such as chemical dosing, water treatment, and oil refining. Key performance indicators include flow rate accuracy, energy consumption, maintenance frequency, and downtime. By analyzing these metrics, industries can determine the optimal pump design and operating conditions to maximize efficiency.

Moreover, the cost-effectiveness of plunger metering pumps extends beyond initial purchase prices. A thorough analysis reveals hidden costs associated with energy usage, upkeep, and potential product losses due to inaccuracies in flow rates. Investing in advanced metering technologies can lead to significant savings over time, as enhanced efficiency translates to reduced operational costs. Ultimately, understanding these efficiency metrics aids industrial operators in making informed decisions, ensuring both productivity and sustainable practices within their processes.

Applications in Various Industries: From Chemical Processing to Water Treatment

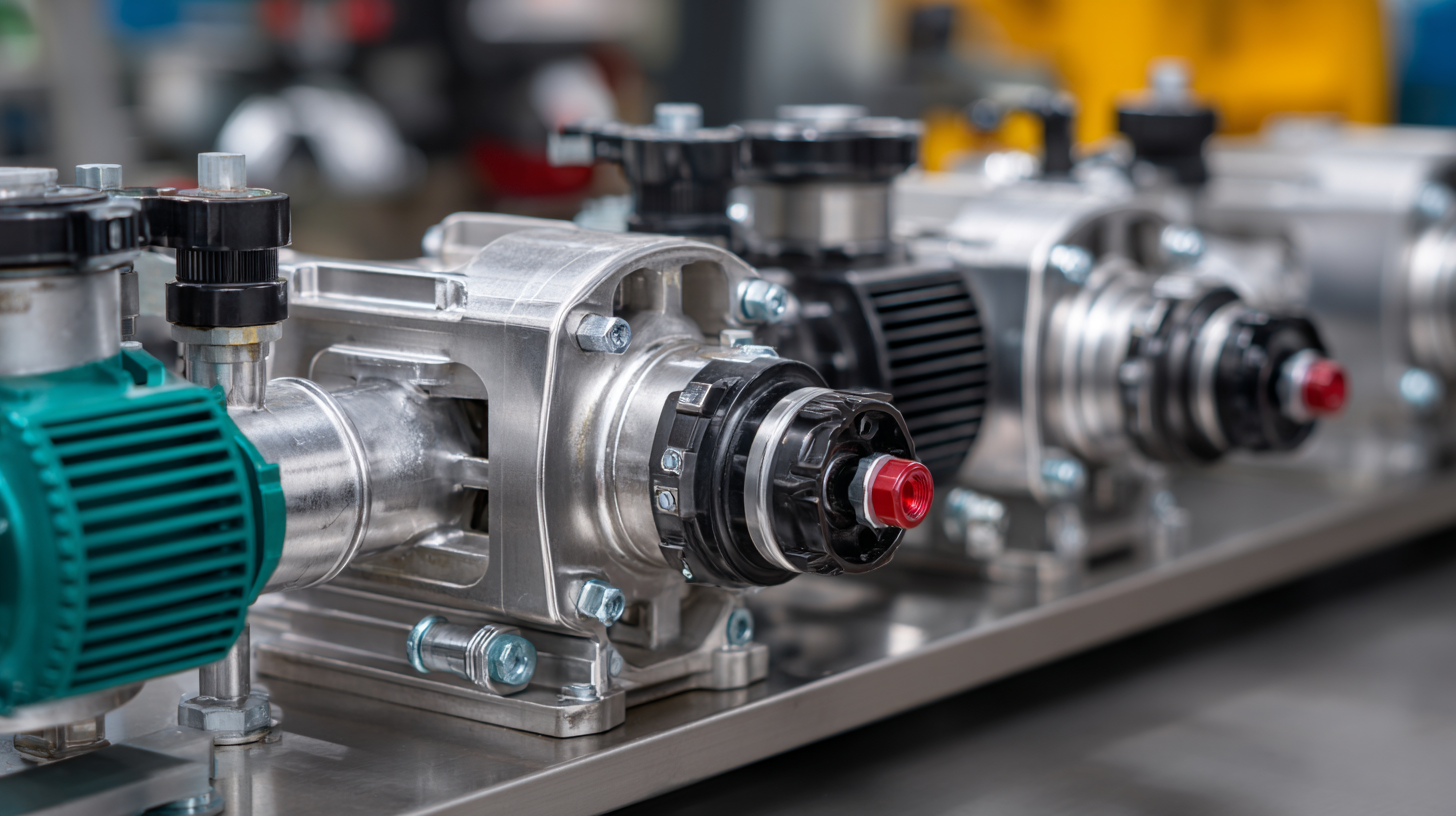

Plunger metering pumps play a crucial role in various industrial applications, particularly in sectors like chemical processing and water treatment. The growing demand for precise dosing mechanisms in these industries has led to an increase in the utilization of such pumps. For instance, in the chemical processing industry, plunger metering pumps ensure the accurate transfer of chemicals, maintaining product quality and consistency. As industries evolve, the need for automation and precision in chemical formulations drives further adoption of these pumps.

In the water treatment sector, the rising market size indicates a significant need for effective dosing systems. The global water treatment market is projected to grow substantially, necessitating reliable equipment that can handle the complexities of water purification and chemical dosing. Plunger metering pumps are increasingly favored for their ability to deliver exact quantities of treatment chemicals, such as flocculants or disinfectants, ensuring compliance with stringent regulations. With innovations tailored for smart and efficient dosing solutions, the relevance of plunger metering pumps in both chemical processing and water treatment continues to expand.

Efficiency and Applications of Plunger Metering Pumps in Various Industries

Maintenance Best Practices for Optimal Pump Operation and Longevity

In the realm of industrial settings, the maintenance of plunger metering pumps is crucial for ensuring optimal operation and longevity. Regular maintenance practices can significantly extend the lifespan of these pumps, which are essential for precise fluid delivery in various applications. According to industry reports, a well-maintained plunger metering pump can achieve operational efficiency exceeding 90%, demonstrating the critical importance of adherence to maintenance protocols.

**Tips:**

- Conduct frequent inspections to identify wear and tear, particularly in seals and check valves. Addressing minor issues promptly can prevent larger failures.

- Implement a routine lubrication schedule for moving parts to minimize friction and enhance performance.

- Monitor pressure and flow rates regularly to ensure the pump operates within its design parameters, enabling early detection of performance issues.

Effective maintenance practices not only boost productivity but also reduce operational costs. In modern pumping systems, integrating new technologies can facilitate better flow control and efficiency, as companies increasingly look to optimize power plant performance and other industrial processes. By focusing on these best practices, organizations can maximize the reliability and efficiency of their plunger metering pumps, contributing to a more sustainable and cost-effective operation.

Future Trends: Innovations in Plunger Metering Pump Technology

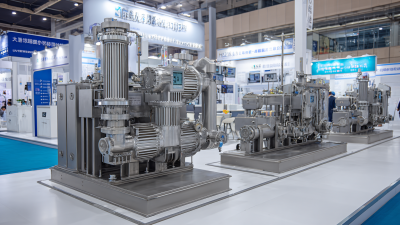

The metering pumps market is experiencing significant growth, projected to reach USD 9.1 billion by 2030. This growth is largely driven by innovations in plunger metering pump technology, which are enhancing efficiency and precision in various industrial settings. These advancements not only optimize fluid handling processes but also allow for improved control over chemical dosing, reducing waste and ensuring compliance with safety standards.

Future trends in plunger metering pump technology indicate a shift towards automation and smart systems. Integrating IoT capabilities enables real-time monitoring and data analysis, facilitating predictive maintenance and minimizing downtime. Additionally, manufacturers are focusing on developing pumps with enhanced materials that resist corrosion and wear, further extending their lifespan and reliability. As industries strive for sustainability, these innovations are crucial in reducing environmental impact while maximizing operational efficiency.

Related Posts

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control

-

Top Strategies for Sourcing High Performance Industrial Pumps Globally

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

How to Select the Right Chemical Metering Pump for Your Application

-

Exploring Plunger Metering Pump Innovations at the 2025 China Import and Export Fair