Blog

- Home

- Blog

Understanding the Essential Role of Pump Hydraulic Systems in Modern Machinery

In the realm of modern machinery, pump hydraulic systems play an indispensable role in ensuring efficiency and reliability across various industrial applications. According to a report by the International Journal of Engineering Research and Applications, hydraulic systems account for approximately 30% of the total energy consumption in industrial settings, underscoring their significance in optimizing performance and reducing operational costs. These systems, which convert mechanical energy into hydraulic energy, enable precise control and powerful actuation, making them vital for equipment ranging from construction machinery to manufacturing processes. As industries increasingly prioritize sustainability and efficiency, understanding the mechanics and applications of pump hydraulic technology becomes essential. This knowledge not only assists in the maintenance and troubleshooting of existing systems but also drives innovation, positioning companies to better adapt to the evolving technological landscape.

Understanding the Basics of Pump Hydraulic Systems in Modern Machinery

Hydraulic systems play a crucial role in the functionality of modern machinery, serving as the backbone for numerous mobile applications. Understanding the basics of these systems, including their components and operation, is essential for both designers and operators. At the heart of hydraulic systems is hydraulic fluid, which not only transmits power but also lubricates and maintains the system. Selecting the appropriate hydraulic oil is vital, as it must provide optimal performance under varying conditions while ensuring longevity and efficiency.

Recent trends in the fluid power industry highlight the shift towards more advanced hydraulic technologies. Experts emphasize the importance of innovative designs that meet the evolving demands of mobile machinery, particularly as electric machines become more prevalent. This integration of hydraulics and electrification presents new challenges and opportunities, making it essential for professionals in the field to leverage their expertise in hydraulics to achieve desired performance attributes. Understanding these dynamics is key to designing robust hydraulic systems that can enhance the performance and reliability of modern machinery.

Understanding the Essential Role of Pump Hydraulic Systems in Modern Machinery

| Parameter | Description | Impact on Machinery | Common Applications |

|---|---|---|---|

| Pressure | The force exerted by the hydraulic fluid | Determines the lifting capacity and speed of machinery | Excavators, cranes |

| Flow Rate | Volume of fluid that moves through the system per minute | Affects the efficiency and responsiveness of hydraulic systems | Forklifts, hydraulic presses |

| Fluid Type | The hydraulic fluid used in the system | Influences lubrication, heat transfer, and system performance | Industrial machinery, automotive sectors |

| Temperature | The operating temperature of the hydraulic fluid | Affects fluid viscosity and system efficiency | Thermal systems, aerospace |

| Tank Size | Capacity of the hydraulic fluid reservoir | Impacts system stability and fluid replacement frequency | Construction, mining equipment |

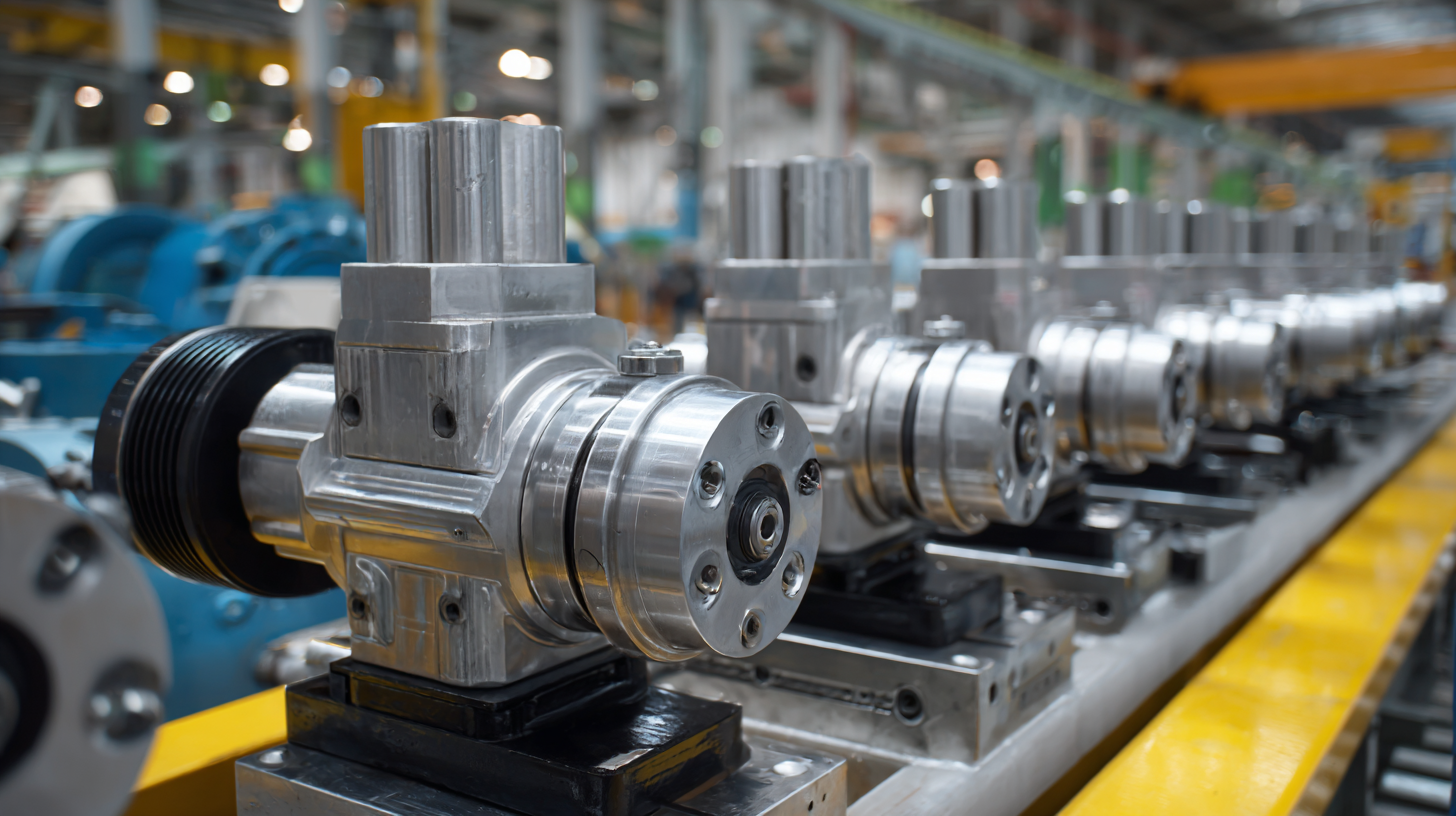

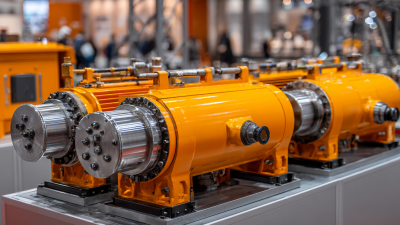

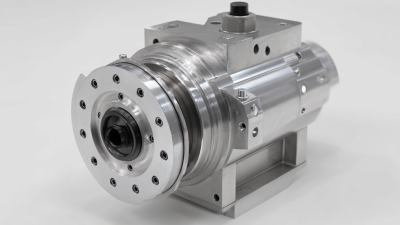

Identifying Key Components of Hydraulic Pump Systems

Hydraulic pump systems are crucial for the efficient operation of modern machinery, with key components including the pump, reservoir, valves, and actuators. The pump acts as the heart of the system, converting mechanical energy into hydraulic energy, which is essential for powering various applications. According to a report by the International Journal of Hydraulic Engineering, around 80% of industrial machines utilize hydraulic systems, highlighting the importance of understanding their components for optimal performance.

The hydraulic reservoir stores hydraulic fluid, ensuring a consistent supply to the pump and preventing overheating. Valves control the flow and direction of the fluid, enabling precise movements and functionality in machinery. Actuators, such as hydraulic cylinders, convert hydraulic energy back into mechanical energy, translating to the desired movement or force. Research from the Hydraulic Institute indicates that proper maintenance of these components can improve system efficiency by up to 20%, underscoring the necessity for industries to prioritize understanding and managing their hydraulic systems effectively.

Examining the Advantages of Hydraulic Systems Over Other Mechanisms

Hydraulic systems are integral to the functionality of modern machinery, providing distinct advantages over traditional mechanical systems. According to a report by the International Fluid Power Society, hydraulic systems deliver a power-to-weight ratio that is significantly higher than that of electric or pneumatic systems, making them ideal for heavy-duty applications. For instance, hydraulic systems can transmit power across long distances without the need for extensive mechanical linkages, reducing the complexity of machinery design and enhancing reliability.

The precision of hydraulic controls is another key benefit. The ability to finely adjust the flow and pressure of hydraulic fluid allows for smooth and controlled movements in applications ranging from excavators to manufacturing equipment. A study published by the National Institute of Standards and Technology highlights that hydraulic systems can achieve a positioning accuracy of less than 0.1 millimeters, which is crucial for industries that require tight tolerances. This level of accuracy minimizes the risk of operational errors, ultimately leading to increased productivity and reduced waste in manufacturing processes.

Troubleshooting Common Issues in Hydraulic Pump Operations

Hydraulic pump systems are integral to the functionality of modern machinery, powering various applications across industries. However, these systems can face common issues that affect their efficiency. According to a recent report from the Hydraulic Institute, nearly 30% of hydraulic system failures stem from improper maintenance practices. This emphasizes the need for proactive troubleshooting techniques.

One prevalent problem is overheating, often caused by excessive fluid viscosity or inadequate cooling. Monitoring the temperature of hydraulic fluids and ensuring they are within recommended levels can significantly enhance the pump's lifespan. Regularly checking for leaks is also crucial, as even minor leaks can lead to substantial drops in system pressure, potentially disrupting operations.

Tips: Always use the manufacturer's recommended hydraulic fluid and maintain a clean environment around the hydraulic components. Implement a routine inspection schedule to identify and resolve issues before they escalate. For instance, analyzing the fluid for contamination monthly can prevent costly downtime and system failures. Regular maintenance and keen observation are the keys to ensuring your hydraulic pump system operates smoothly.

Maintaining and Optimizing Hydraulic Systems for Peak Performance

Maintaining and optimizing hydraulic systems is crucial for ensuring peak performance in modern machinery. To achieve this, regular inspections and preventive maintenance should be prioritized. Monitoring fluid levels, assessing for leaks, and checking filter conditions play a significant role in extending the lifespan of hydraulic components. A proactive approach can prevent minor issues from escalating into major failures, thus avoiding costly downtime.

Maintaining and optimizing hydraulic systems is crucial for ensuring peak performance in modern machinery. To achieve this, regular inspections and preventive maintenance should be prioritized. Monitoring fluid levels, assessing for leaks, and checking filter conditions play a significant role in extending the lifespan of hydraulic components. A proactive approach can prevent minor issues from escalating into major failures, thus avoiding costly downtime.

Tips: One effective strategy is to implement a scheduled maintenance plan that includes routine fluid analysis and system diagnostics. Additionally, using high-quality hydraulic fluids can enhance system efficiency and reduce wear and tear. Make sure to keep your machinery clean, as debris can hinder functionality, leading to potential malfunctions in the hydraulic system.

Furthermore, optimizing the operational parameters such as pressure settings and flow rates can significantly improve overall performance. Operators should be trained to recognize signs of stress or inefficiencies in the system, allowing for timely adjustments. Implementing real-time monitoring technology can also assist in tracking system health, helping to ensure that your hydraulic systems operate at their peak capabilities.

Related Posts

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

How to Optimize Your Hydraulic Pump System for Maximum Efficiency

-

How to Choose the Right Hydraulic Pump for Your Industrial Needs

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

Understanding the Benefits of High Flow Hydraulic Pump in Modern Industrial Applications