Blog

- Home

- Blog

Top 7 Expert Tips for Using High Pressure Diaphragm Pumps Effectively

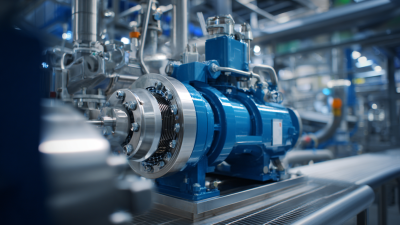

High Pressure Diaphragm Pumps (HPDPs) play a crucial role in various industrial applications, offering reliable performance and versatility in handling a multitude of fluids. According to a recent market report by Grand View Research, the global diaphragm pump market is poised to reach USD 6.61 billion by 2025, driven by increasing demand for high-pressure solutions across sectors such as chemical processing, water treatment, and food and beverage. This growth underscores the importance of understanding and maximizing the efficiency of HPDPs to ensure optimal operation and safety.

As industries strive for improved productivity and cost-effectiveness, it is imperative for operators to harness the full potential of High Pressure Diaphragm Pumps. Proper usage not only enhances performance but also extends the life of the equipment, dramatically reducing maintenance costs. Furthermore, with advancements in pump technology, such as the development of more durable materials and innovative designs, stakeholders must stay abreast of expert recommendations to keep pace with the evolving landscape. This article presents the top seven expert tips for using HPDPs effectively, equipping operators with the knowledge necessary to leverage these powerful tools in their operations.

Understanding Diaphragm Pump Mechanics for Optimal Performance

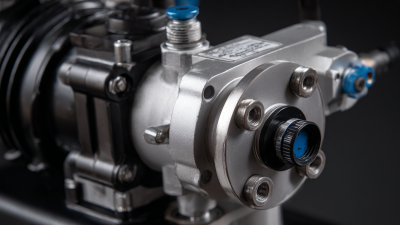

Understanding the mechanics of high pressure diaphragm pumps is crucial for achieving optimal performance in various applications. These pumps operate based on a simple yet effective principle: they use a flexible diaphragm that alternately expands and contracts to create a vacuum and subsequently push fluid through the system. This mechanism not only ensures a positive displacement of fluids but also allows for handling a wide range of liquids, including those that are abrasive or corrosive. By grasping these fundamental operations, users can better troubleshoot issues and maintain their pumps for prolonged efficacy.

To maximize the performance of diaphragm pumps, it's essential to consider factors such as the diaphragm material, pump size, and the type of fluid being conveyed. Selecting the right diaphragm material can significantly impact the pump’s durability and its capability to handle specific chemicals or temperatures. Similarly, ensuring that pump size matches your application requirements helps prevent issues like cavitation or loss of prime. Through a deep understanding of these mechanical aspects, users can optimize pump settings, maintain efficiency, and extend the lifespan of their diaphragm pumps, leading to more reliable and cost-effective operations.

Performance Metrics of High Pressure Diaphragm Pumps

Key Factors Influencing the Efficiency of High Pressure Diaphragm Pumps

High-pressure diaphragm pumps have become essential in various industrial applications, primarily due to their efficiency and reliability. Several key factors influence the effectiveness of these pumps, including operational pressure, fluid viscosity, and diaphragm material. For instance, the global diaphragm pump market is projected to grow significantly, indicating a surge in demand for efficient pumping solutions as industries expand. The market was valued at approximately $6.27 billion in 2023 and is estimated to reach upwards of $9.97 billion by 2032. This growth underscores the importance of selecting the right pump based on specific operational needs.

Moreover, innovations in diaphragm pump technology, such as low pulsation designs, enhance operational efficiency. Recent advancements have led to the development of new diaphragm pumps tailored for the chemical and industrial sectors. With features that ensure smooth flow and reduced fluid turbulence, these pumps can significantly improve process efficiency. As industrialization continues to accelerate, focusing on these key factors will be crucial for optimizing the performance of high-pressure diaphragm pumps across various applications.

Proper Maintenance Practices to Extend the Life of Your Diaphragm Pump

Proper maintenance practices are crucial for extending the lifespan of high pressure diaphragm pumps. Regular inspections and timely servicing can significantly reduce downtime and operational costs. According to a report by the Hydraulic Institute, over 30% of pump failures are attributed to improper maintenance, emphasizing the need for a well-structured maintenance schedule. Routine tasks should include checking for leaks, ensuring that the fluid levels are adequate, and monitoring the performance metrics such as pressure and flow rates.

Moreover, specific maintenance practices can help in identifying issues before they escalate. For example, regularly replacing worn-out diaphragms can prevent material fatigue, which is a leading cause of pump failure in high-pressure applications. A study conducted by the Pump Systems Matter program showed that implementing a proactive maintenance program can improve pump efficiency by up to 15%, placing a strong emphasis on preventative care. Investing in proper training for maintenance staff will ensure that these practices are not only followed but also optimized for the specific operational demands of your diaphragm pumps, driving long-term reliability and efficiency.

Safety Considerations When Operating High Pressure Diaphragm Pumps

When operating high pressure diaphragm pumps, safety should be the foremost consideration. These pumps are capable of handling various fluids at significantly high pressures, which can pose substantial risks. First, operators must ensure proper training and awareness of the pump's specific functionalities and limitations. Understanding the operating manual and adhering to manufacturer guidelines can mitigate risks associated with mishandling and equipment failure.

Additionally, regular maintenance checks are crucial for safe operation. Inspecting hoses, connections, and safety valves will help prevent leaks and potential pressure surges. It’s vital to utilize personal protective equipment (PPE) such as gloves, goggles, and face shields to protect against any accidental splashes or pressurized fluid release. Furthermore, establishing a clear emergency response plan and ensuring that all team members are familiar with it can significantly enhance safety during pump operation. By prioritizing these considerations, operators can create a safer working environment while maximizing the effectiveness of high pressure diaphragm pumps.

Best Applications for High Pressure Diaphragm Pumps in Various Industries

High pressure diaphragm pumps offer a versatile solution across various industries due to their ability to handle a wide range of fluids, including corrosive and viscous materials. In the chemical processing sector, for instance, these pumps are utilized for transferring aggressive chemicals and maintaining high pressure levels, which is essential for processes where fluid dynamics are critical. A recent market report indicated that the demand for high pressure diaphragm pumps in chemical applications is projected to grow at a CAGR of 6.5% through 2028, driven by the increasing need for safe and efficient fluid handling systems.

In the food and beverage industry, high pressure diaphragm pumps are integral for transporting viscous substances like pastes and creams, ensuring minimal damage to the product. Their sanitary design and ability to operate without compromising the integrity of delicate ingredients make them a top choice for manufacturers. According to industry analysts, the food processing segment accounts for over 20% of the total diaphragm pump market, reflecting an increasing reliance on these pumps for maintaining both quality and operational efficiency.

Top 7 Expert Tips for Using High Pressure Diaphragm Pumps Effectively

| Tip Number | Expert Tip | Best Applications |

|---|---|---|

| 1 | Ensure proper sizing of diaphragm pumps for your application. | Water treatment, chemical processing |

| 2 | Regularly inspect and maintain diaphragms to avoid failures. | Pharmaceuticals, food & beverage |

| 3 | Utilize pulsation dampeners to improve flow consistency. | Oil & gas, mining |

| 4 | Monitor temperature and pressure to prevent overheating. | Chemical injection, wastewater management |

| 5 | Choose suitable materials for diaphragms based on chemicals being pumped. | Textile industry, surface coating |

| 6 | Optimize inlet and outlet conditions to minimize cavitation. | Aquaculture, agriculture |

| 7 | Training operators on pump operation enhances performance. | General manufacturing, construction |

Related Posts

-

7 Best Practices for Choosing a High Pressure Metering Pump

-

Unlocking Efficiency: How High Pressure Pumps Revolutionize Industrial Processes

-

Understanding the Advantages of Hydraulic Diaphragm Pumps in Modern Industrial Applications

-

Understanding the Importance of High Pressure Dosing Pumps in Modern Industries

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

Unlocking Efficiency: The Significant Advantages of Plunger Metering Pumps in Process Industries