In the rapidly evolving landscape of industrial processes, the demand for efficient and reliable Chemical Pumps has surged, with the global market projected to reach USD 6.5 billion by 2026, growing at a CAGR of 4.5% from 2021. As industries increasingly recognize the critical role that chemical pumps play in handling various fluids safely and effectively, understanding the benefits of selecting the right type becomes paramount.

Factors such as energy efficiency, durability, and adaptability to different chemical compositions are essential for optimizing operational performance. Moreover, a recent market analysis indicated that over 70% of businesses reported significant cost savings after switching to more advanced chemical pump technologies.

Consequently, sourcing the best chemical pump globally requires a strategic approach that not only considers economic factors but also emphasizes sustainability and technological advancements in pump design.

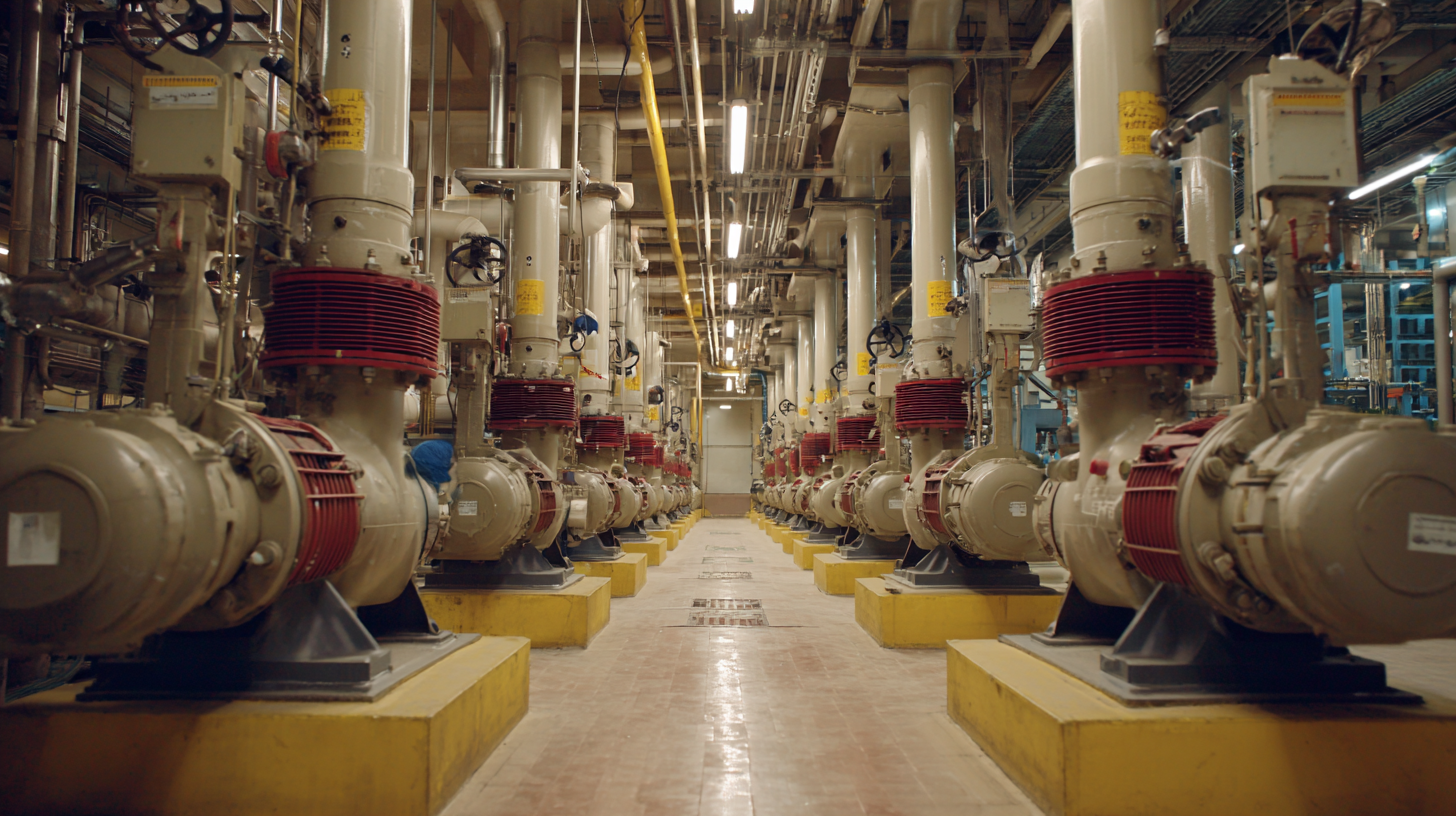

When sourcing the best chemical pump globally, it’s crucial to first identify your specific needs. Different applications require different types of chemical pumps, whether it's for transferring corrosive liquids or handling high-viscosity fluids. Understanding the flow rate, pressure requirements, and compatibility with the chemicals to be pumped is essential. This comprehensive guide aims to lead you through this crucial first step.

**Tips:** Start by conducting a thorough analysis of the chemicals you work with. Consider their temperature, corrosiveness, and particle size, as these factors play a vital role in selecting the right pump. Engaging with manufacturers who can provide insights into their product specifications can also streamline your selection process.

Next, evaluate the pump's efficiency and reliability. Look for options that include features such as NPSH (Net Positive Suction Head) calculations, which are vital in ensuring the pump performs optimally without cavitation. Always consider the ease of maintenance; a pump that's easy to service can save significant time and costs in the long run.

When it comes to sourcing the best chemical pumps globally, evaluating potential suppliers is crucial to ensuring a successful partnership. One of the primary criteria to consider is the manufacturer’s experience and reputation in the industry. A supplier with a proven track record and positive customer reviews will likely demonstrate reliability and product quality. It’s essential to research their history, specific chemical pump applications, and any certifications they hold, as these factors can significantly influence performance and durability.

Another important aspect to assess is the manufacturer’s technology and innovation capabilities. The best chemical pump suppliers should be committed to continuous improvement and invested in modern manufacturing processes. This includes utilizing advanced materials, energy-efficient designs, and customizable features that cater to your specific operational needs. Additionally, ensure they offer strong technical support and after-sales services, as this can make a substantial difference in the long-term effectiveness of the equipment and your overall satisfaction with the supplier.

In recent years, leveraging technology has revolutionized the way companies source chemical pumps globally. Advanced software solutions, such as artificial intelligence and machine learning, have enabled businesses to analyze vast amounts of data, making it easier to identify the best suppliers based on performance, cost, and reliability. By utilizing predictive analytics, organizations can forecast demand more accurately, ensuring they have the right pumps in stock when needed, thus minimizing downtime and enhancing operational efficiency.

Furthermore, the rise of digital platforms has facilitated direct connections between manufacturers and buyers, reducing reliance on intermediaries and streamlining the procurement process. These platforms often feature user-friendly interfaces that allow for real-time comparisons of product specifications, prices, and supplier ratings. Innovations such as 3D printing also play a significant role, enabling customized pump designs that meet specific operational requirements. As the industry continues to evolve, staying ahead of these technological trends will be essential for sourcing the best chemical pumps efficiently and effectively.

When it comes to sourcing the best chemical pump globally, achieving cost efficiency while maintaining high quality is paramount. Companies often face the challenging task of selecting pumps that meet their operational needs without exceeding their budget. One effective strategy is to thoroughly assess the total cost of ownership (TCO). This includes not only the initial purchase price but also maintenance, energy consumption, and potential downtime costs over the pump’s lifespan.

Another tip is to explore multiple suppliers. By expanding the supplier base, businesses can compare prices, negotiate better deals, and identify options that offer the best value for money. Engaging with suppliers who have a strong reputation for quality can also pay off in the long run, reducing maintenance costs and enhancing reliability.

Additionally, considering refurbished or second-hand pumps can lead to significant savings without compromising on quality. Many reputable suppliers offer certified used pumps that have been thoroughly tested and refurbished, providing an excellent alternative for budget-conscious companies. Balancing these strategies can significantly optimize your pump procurement process, ensuring that quality and budget constraints are effectively managed.

In the global market for chemical pumps, understanding regional dynamics is crucial for effective sourcing strategies. Recent research indicates that the global self-priming pump market is projected to reach USD 38.86 billion by 2033, growing at a CAGR of 5.01%. This growth underlines the increasing demand for efficient pumping solutions across various industries, including water treatment and oil extraction.

Different regions present unique challenges and opportunities when sourcing chemical pumps. For instance, the industrial heat pump market is expected to grow from USD 9.5 billion in 2023 to USD 19.3 billion by 2033, reflecting a robust CAGR of 7.4%. This regional insight illustrates the importance of tailoring procurement strategies to local market conditions, ensuring that companies meet their operational needs effectively and economically.

**Tips:**

1. Assess local market trends and demands to identify the most suitable pump types for your operations.

2. Leverage regional supplier networks to ensure reliability and quality in sourcing chemical pumps.

3. Keep abreast of technological advancements within the pump industry to enhance efficiency and sustainability in your sourcing strategies.

Copyright © 2023 TUF Pump Industry (Jiangsu) Co., Ltd. - Stainless Steel Centrifugal Pump, Chemical Pump, Metering Pump - All Rights Reserved.