Blog

- Home

- Blog

Ultimate Guide to Selecting the Right Industrial Dosing Pump for Your Needs

In today's manufacturing landscape, the efficiency and accuracy of fluid management can significantly impact productivity and operational costs. This makes the choice of the right equipment crucial, especially when it comes to an Industrial Dosing Pump. With a variety of options available on the market, selecting the right pump to meet your specific dosing needs can be a daunting task.

Whether you are dealing with corrosive chemicals, viscous fluids, or precise metering applications, understanding the key features and specifications of different pumps is essential. This ultimate guide aims to simplify your decision-making process by highlighting the best types of Industrial Dosing Pumps, addressing their applications, and providing practical tips for selection. By the end of this guide, you'll be equipped with the knowledge needed to make an informed choice that enhances your operational efficiency and effectiveness.

Understanding the Different Types of Industrial Dosing Pumps Available

When selecting an industrial dosing pump, understanding the different types available is crucial to meeting specific operational needs. The primary categories include

peristaltic pumps,

diaphragm pumps,

and

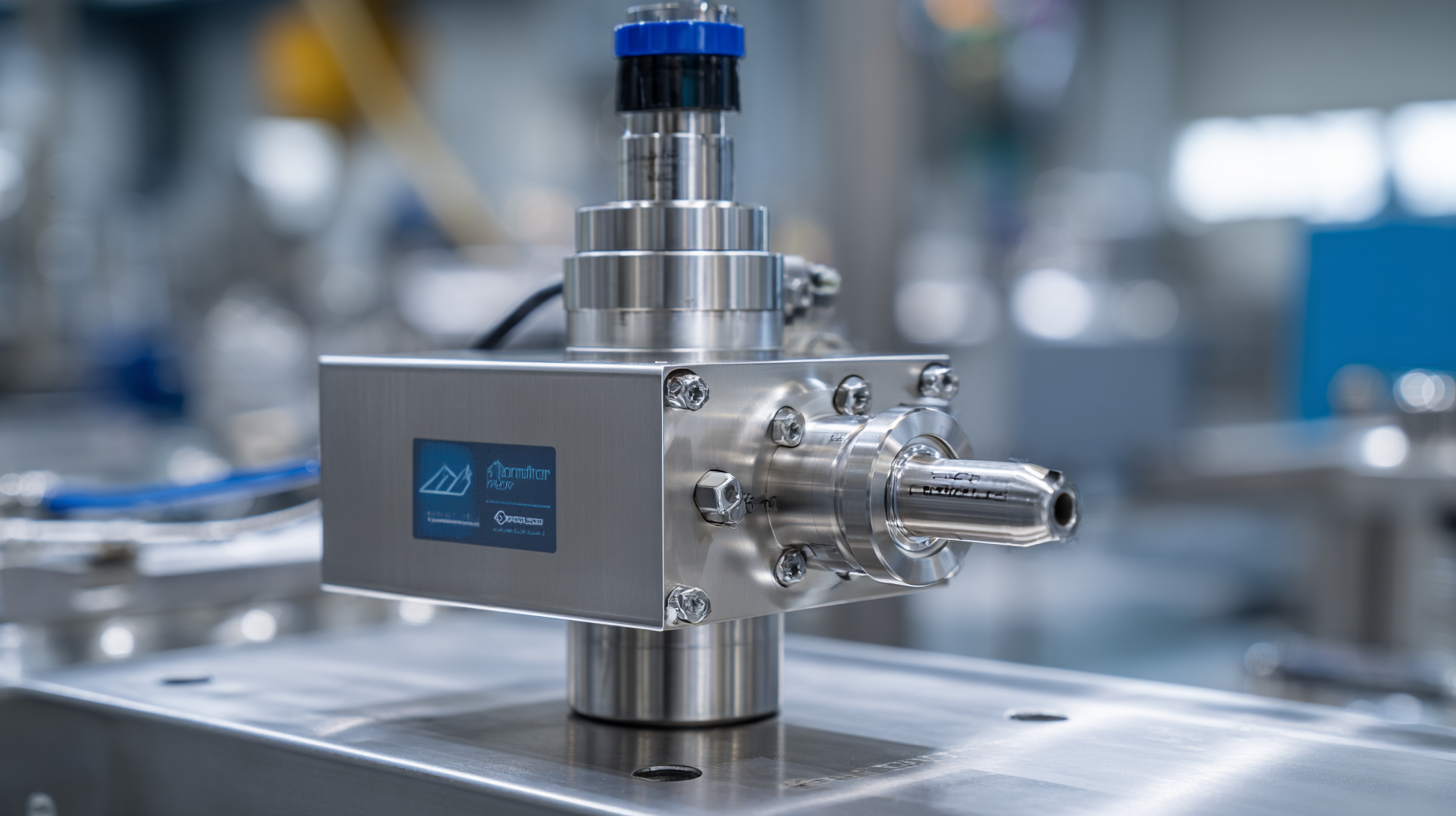

gear pumps, each offering unique advantages.

Peristaltic pumps, for example, are widely used due to their ability to handle shear-sensitive fluids without contamination, making them ideal for sensitive applications. They operate by squeezing flexible tubing, which provides a precise and consistent dosing flow.

Diaphragm pumps are another popular choice in the industry, known for their ability to handle a wide range of chemicals and their robustness in harsh environments. They utilize a flexible diaphragm to create suction and discharge, ensuring minimal leakage and high accuracy in dosing applications.

Gear pumps, while often used for viscous liquids, provide reliable flow rates and can be designed for high-pressure applications. Understanding these types will help businesses choose the right pump based on the fluid properties, required flow rates, and environmental conditions to optimize productivity and efficiency.

Key Factors to Consider When Choosing an Industrial Dosing Pump

When choosing the right industrial dosing pump, several key factors come into play to ensure optimal performance and efficiency. Firstly, flow rate is paramount, as it determines the volume of liquid dispensed over time. Data from the Global Industrial Pump Market report suggests that the demand for pumps with flow rates between 10-200 liters per hour continues to rise, primarily due to increased processing needs in various industries like chemicals and pharmaceuticals. Selecting a pump that aligns with your specific flow requirements not only enhances operational efficiency but also minimizes waste.

Another critical consideration is the nature of the fluid being pumped. For example, corrosive or viscous liquids require materials and designs specifically tailored to withstand their properties. According to a report by Grand View Research, the industrial dosing pump market is expected to grow significantly, with an emphasis on pumps that can handle challenging fluids using advanced materials. Additionally, the pump's compatibility with automation systems can lead to improved precision in dosing, which is essential for maintaining product quality in manufacturing processes. Understanding these factors can significantly impact the selection process and the overall success of industrial operations.

Industrial Dosing Pumps Comparison

This chart compares three different types of industrial dosing pumps based on various parameters, including flow rate, maximum pressure, power consumption, and price. Use this information to make an informed decision when selecting the right dosing pump for your applications.

Assessing Compatibility with Your Specific Fluid and Application

When selecting the right industrial dosing pump, assessing compatibility with your specific fluid and application is paramount. Compatibility not only influences the pump's performance but also affects the longevity and reliability of the entire system. For instance, recent studies have highlighted the importance of evaluating the interaction between different fluids and materials in various industrial contexts. For example, choline-based deep eutectic solvents have shown potential in maintaining enzyme stability under high temperatures, illustrating how specific fluid characteristics can dictate the suitability of dosing systems.

In oil and gas applications, the compatibility between formation water and injection water is crucial. Research indicates that scale deposition is a major challenge in water injection systems. Thus, understanding the chemical interactions and potential scaling effects can help in selecting the appropriate dosing pump that minimizes such risks. The growing body of knowledge surrounding fluid compatibility provides valuable insights that can aid professionals in making informed decisions, ensuring operational efficiency and system integrity while meeting their unique application requirements.

Evaluating Accuracy, Flow Rate, and Pressure Requirements

When selecting the right industrial dosing pump, it’s essential to evaluate three critical factors: accuracy, flow rate, and pressure requirements. Accuracy is crucial because even a slight deviation in chemical dosing can lead to significant operational issues, impacting product quality and safety. According to the International Journal of Chemical Engineering, pumps with an accuracy rate of ±1% are ideal for most applications, ensuring that your processes are reliable and consistent.

Flow rate is another vital consideration, as it determines how much fluid can be moved in a given time frame. Depending on your application, the flow rate may range from a few milliliters per minute to several liters per minute. The American Society of Mechanical Engineers emphasizes that selecting a pump with a flow rate beyond your maximum requirement can help accommodate fluctuations in demand, enhancing overall system efficiency.

Tips: When assessing your pump's pressure requirements, always take into account the total dynamic head (TDH) to avoid underperformance. Additionally, consider investing in a pump with adjustable flow settings to optimize performance across various operating conditions. Monitoring your system’s performance regularly can also aid in maintaining the desired accuracy and efficiency.

Maintenance Tips for Ensuring Longevity of Your Dosing Pump

Maintaining the longevity of your industrial dosing pump is critical to ensuring reliable performance and maximizing your investment. According to a report by the Hydraulic Institute, approximately 80% of pump failures are attributed to improper maintenance practices. Regularly scheduled maintenance can significantly extend the life of your pump, reducing the frequency and cost of replacements. Key maintenance strategies include routine inspections of seals and components, ensuring that all connections are secure, and monitoring the pump’s operational parameters to detect potential issues early.

Another essential maintenance tip is to maintain the correct chemical compatibility, as per the Chemical Engineering Research and Design Journal, incorrect chemical use can lead to accelerated wear and tear on pump components. It is advisable to use dosing pumps made from materials that can withstand the specific chemicals being handled. Furthermore, applying appropriate lubrication and ensuring that the pump is free from debris can prevent common operational failures, which, according to the American Society of Mechanical Engineers, can reduce downtime by up to 30%. Regular training for operators on handling and maintaining the dosing pump can further enhance its reliability and lifespan.

Related Posts

-

7 Best Industrial Pumps You Should Consider for Your Next Project

-

Top Strategies for Sourcing High Performance Industrial Pumps Globally

-

7 Best Dosing Pumps for Precision Chemical Dispensing

-

5 Best Chemical Pumps for Efficient Industrial Use

-

Understanding Common Issues Faced by Users of Plunger Pumps

-

Ultimate Guide to Selecting the Right Hydraulic Diaphragm Pump for Your Industrial Needs