Blog

- Home

- Blog

Top 10 High Flow Hydraulic Pumps for Enhanced Performance and Efficiency

In the realm of hydraulic machinery, the demand for enhanced performance and efficiency has propelled the development of High Flow Hydraulic Pumps to the forefront of industrial innovation. According to a recent report by the International Fluid Power Society, the global market for hydraulic pumps is projected to reach USD 18 billion by 2025, with a significant portion attributed to high flow models which cater to heavy-duty applications. This surge in demand underscores the critical role that High Flow Hydraulic Pumps play in optimizing productivity across various sectors, particularly in construction, manufacturing, and agriculture.

Expert insights into this evolving landscape come from Dr. Samuel H. White, a leading authority in hydraulic systems, who emphasizes, "The efficiency gains realized through the implementation of high flow hydraulic pumps can greatly reduce operational costs and enhance system reliability." As industries strive for greater sustainability and efficiency, high flow options present a strategic advantage, offering superior flow rates while maintaining energy efficiency.

This article will explore the top 10 high flow hydraulic pumps that not only exemplify performance but also contribute to improved operational efficiency. By examining these models, we aim to provide insights into how selecting the right hydraulic pump can lead to significant advancements in operational effectiveness for industries worldwide.

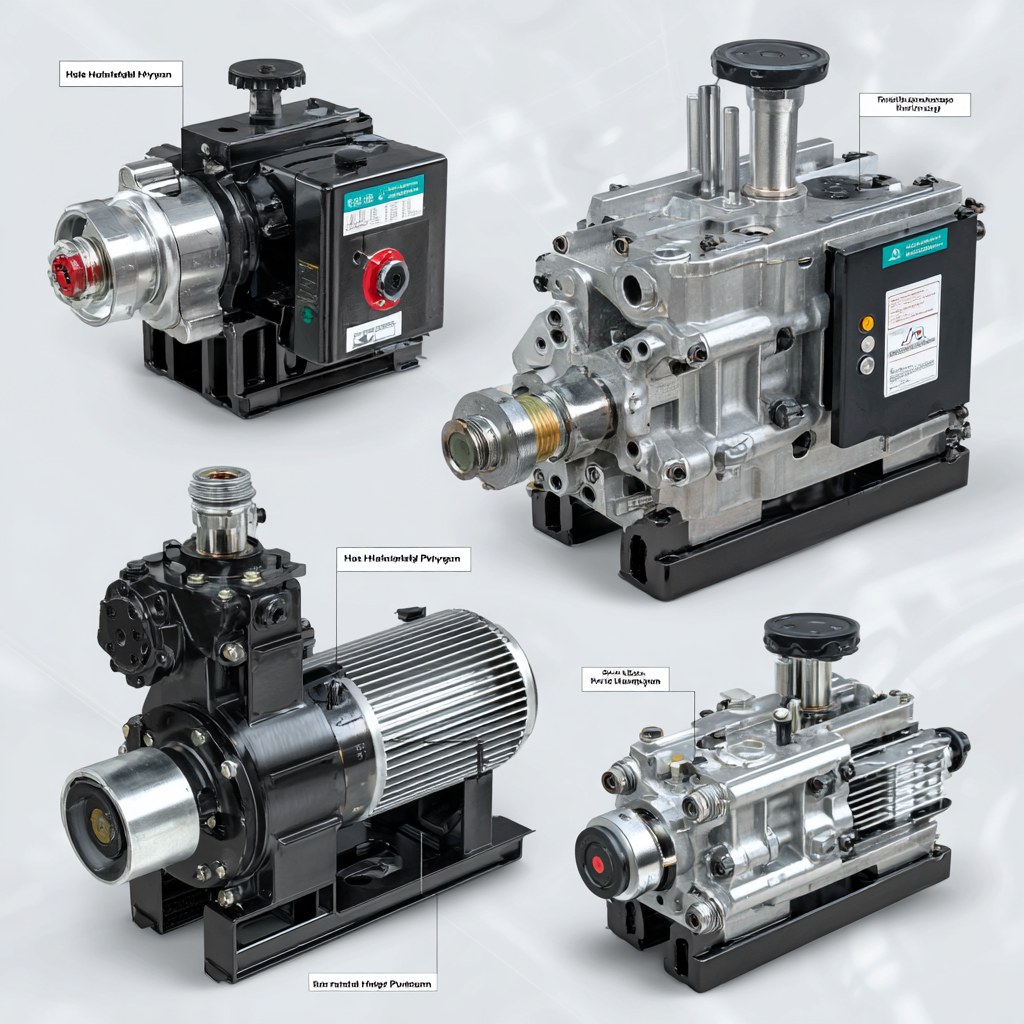

High Flow Hydraulic Pumps: Key Features and Benefits for Improved Performance

High flow hydraulic pumps are essential components in many industrial applications, offering significant improvements in performance and efficiency. One of the key features of these pumps is their ability to provide a higher flow rate compared to standard pumps, allowing for quicker hydraulic action and enhanced power delivery. This is particularly beneficial in systems that require rapid movement or high-pressure operation, such as construction equipment, agricultural machinery, and manufacturing processes. By reducing cycle times, businesses can increase productivity and output without compromising on the quality of work.

Additionally, high flow hydraulic pumps come with advanced design elements that contribute to their reliability and longevity. Many models are equipped with variable displacement features, enabling adjustable flow rates to suit specific operational needs. This adaptability not only optimizes energy consumption but also minimizes wear and tear on the equipment. Furthermore, robust construction materials and efficient cooling systems enhance the pumps’ durability, making them a cost-effective investment for operators seeking to improve their hydraulic systems' performance and efficiency.

Top 10 High Flow Hydraulic Pumps for Enhanced Performance and Efficiency

| Pump Model | Flow Rate (GPM) | Pressure Rating (PSI) | Efficiency (%) | Weight (lbs) | Key Feature |

|---|---|---|---|---|---|

| Model A | 30 | 3000 | 95 | 50 | High Efficiency |

| Model B | 40 | 2500 | 90 | 65 | Compact Design |

| Model C | 25 | 3500 | 92 | 55 | Durable Construction |

| Model D | 50 | 2000 | 88 | 70 | Low Noise Operation |

| Model E | 35 | 2800 | 91 | 60 | Corrosion Resistant |

| Model F | 20 | 3200 | 89 | 48 | Fast Response |

| Model G | 45 | 2700 | 93 | 68 | Versatile Applications |

| Model H | 10 | 3600 | 85 | 40 | High Pressure Capability |

| Model I | 55 | 2900 | 94 | 73 | Extended Lifespan |

| Model J | 15 | 3100 | 87 | 42 | Easy Maintenance |

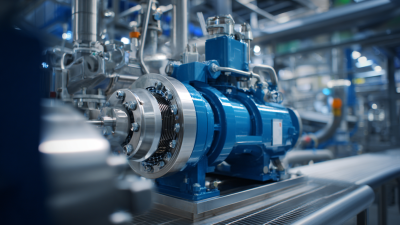

Innovative Technologies Driving High Efficiency in Hydraulic Pump Design

The landscape of hydraulic pump technology is continuously evolving, driven by the demand for enhanced performance and efficiency. Innovative technologies, such as variable displacement mechanisms and advanced materials, are reshaping hydraulic pump design. These advancements not only increase flow rates but also optimize energy consumption, making hydraulic systems more sustainable and cost-effective.

Tips: When selecting a hydraulic pump, consider the operational environment. Factors like temperature, pressure fluctuations, and fluid compatibility can significantly affect performance. Ensure that the pump's design accommodates these variables to enhance its lifecycle and efficiency.

Moreover, the integration of smart technologies, such as IoT sensors and predictive analytics, is paving the way for real-time monitoring and maintenance. This proactive approach allows operators to identify inefficiencies and potential failures before they escalate. Investing in pumps equipped with these features can lead to significant operational savings and improved system reliability.

Tips: Regular maintenance is crucial for maintaining high efficiency in hydraulic systems. Schedule routine check-ups and keep a close watch on fluid levels and filter conditions to prevent performance degradation. Prioritize pumps with self-diagnostic capabilities to streamline upkeep and reduce downtime.

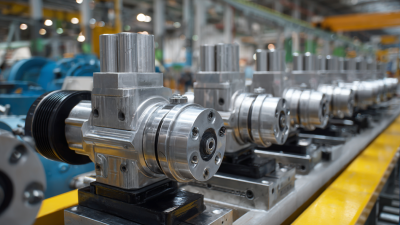

Top 10 High Flow Hydraulic Pumps for Industrial Applications in 2025

When it comes to industrial applications in 2025, selecting the right high flow hydraulic pump is crucial for maximizing productivity and efficiency. These pumps are designed to handle substantial fluid volumes, making them ideal for heavy-duty operations in manufacturing, construction, and mining sectors. The advancements in hydraulic technologies ensure that these pumps not only deliver higher flow rates but also maintain reliability and energy efficiency. As industries evolve, so does the need for pumps that can adapt to varying operational demands while minimizing downtime.

Tips: When choosing a high flow hydraulic pump, consider the system's compatibility with your existing equipment to prevent performance issues. Regular maintenance is also key; neglecting this can lead to wear and inefficiencies that impact overall performance.

In 2025, expect to see a surge in smart hydraulic pumps equipped with IoT capabilities, offering real-time monitoring and diagnostics. This innovation allows for proactive management, reducing the risk of unexpected failures and optimizing operational workflows. As technology advances, industrial users will have a broader selection, enabling tailored solutions that fulfill specific needs while promoting sustainability in hydraulic operations.

Tips: Always assess the total cost of ownership, including maintenance and energy consumption, when investing in high flow hydraulic pumps. This comprehensive view ensures that you make a financially sound decision while enhancing the operational efficiency of your industrial projects.

Comparison of Flow Rates and Operating Costs in Leading Hydraulic Pumps

When selecting hydraulic pumps, flow rate and operating costs are pivotal in determining overall performance and efficiency. According to a recent report by the Hydraulic Institute, high-flow hydraulic pumps can significantly impact operational productivity, as models with flow rates exceeding 100 gallons per minute (GPM) are becoming increasingly prevalent in industries such as construction and manufacturing. These pumps not only improve the speed of operations but also reduce the energy required to achieve the desired output, thus lowering overall costs.

A comparative analysis highlights that high-flow hydraulic pumps can lead to as much as a 20% reduction in operating costs due to improved efficiency and reduced downtime. For instance, the latest models equipped with variable displacement technology allow operators to adjust flow rates dynamically, optimizing performance based on current demands. This adaptability not only enhances efficiency but also prolongs the equipment's lifespan, further minimizing maintenance expenses. Industry reports underline that investing in high-efficiency hydraulic pumps can provide a return on investment (ROI) of up to 30% within the first year of operation, marking them as a crucial component for businesses aiming to enhance their operational efficiency and reduce costs.

Future Trends in High Flow Hydraulic Pump Technologies and Sustainability

The future of high flow hydraulic pump technologies is increasingly intertwined with sustainability and advanced innovations. AI-powered operational intelligence is set to revolutionize pump performance, enabling real-time data analytics that enhance efficiency and predict maintenance needs. This technological integration not only improves the operational lifespan of hydraulic pumps but also fosters a more sustainable approach to resource management. As industries lean towards smart solutions, decentralized infrastructure becomes a focal point, allowing for localized control and responsiveness to water management challenges such as flood prevention.

Moreover, the shift towards sustainability is reflected in the industrial pumps market's evolution. The exploration of renewable energy sources, such as biofuels, emphasizes the commitment to greener alternatives. This aligns with the growing recognition of sustainable water treatment methods that enhance overall ecosystem health. As regulatory frameworks evolve and industry players adapt, the integration of these advanced technologies promises to create a more robust and sustainable future for hydraulic pumps, solidifying their vital role in diverse applications across various sectors.

Related Posts

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

5 Best Tips for Choosing the Right Hydraulic Pump for Your Needs

-

Understanding the Essential Role of Pump Hydraulic Systems in Modern Machinery

-

5 Essential Tips for Sourcing the Best Pump Water Solutions Globally

-

Innovative Solutions for Plunger Metering Pump Applications

-

Unlocking Efficiency: How High Pressure Pumps Revolutionize Industrial Processes