Blog

- Home

- Blog

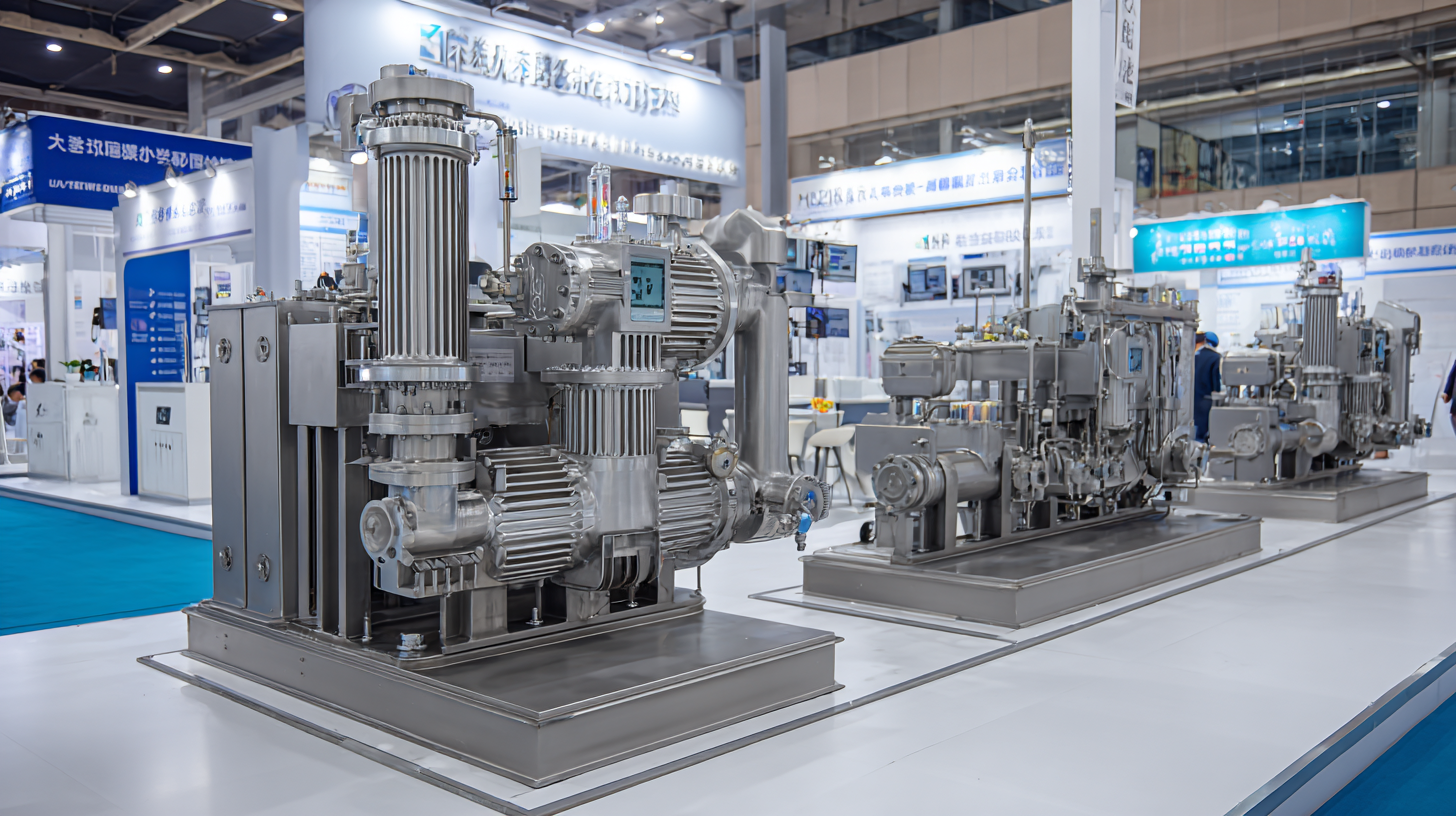

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025

The 138th China Import and Export Fair in 2025 serves as a pivotal platform to explore technological advancements and market trends across various industries, with a particular focus on Diaphragm Metering Pumps. According to a recent industry report from MarketsandMarkets, the global diaphragm metering pump market is expected to reach USD 4.4 billion by 2025, growing at a CAGR of 6.2% from 2020. This growth is driven by increasing demand in sectors such as water treatment, oil and gas, and chemical processing, which require precise fluid control solutions.

The event not only highlights the latest innovations in diaphragm metering technology but also provides insights into best practices and applications that can enhance operational efficiency. As companies seek to optimize their processes and reduce waste, understanding the capabilities and advantages of diaphragm metering pumps will be crucial for achieving sustainable growth in the coming years.

Impact and Advantages of Diaphragm Metering Pumps in Industrial Applications

Diaphragm metering pumps are revolutionizing industrial applications, offering

precision and reliability that enhance various processes. These pumps are designed to deliver a consistent flow rate, which is crucial

for industries such as chemical manufacturing, pharmaceuticals, and water treatment. Their ability to handle a wide range of viscosities

and corrosive fluids without compromising performance makes them an ideal choice for demanding environments. By ensuring accurate chemical dosing,

diaphragm metering pumps minimize waste and reduce costs, contributing to overall operational efficiency.

In addition to precision, diaphragm metering pumps provide significant advantages in terms of maintenance and safety. Their construction

typically involves fewer moving parts, leading to lower wear and tear, which translates to decreased downtime and maintenance costs.

Moreover, these pumps can operate under high pressure and adverse conditions, which enhances their durability and lifespan. The

event at the 138th China Import and Export Fair 2025 will showcase innovative

designs and advancements in diaphragm metering pump technology, emphasizing their critical role in pushing industrial boundaries

and improving productivity across various sectors.

Key Technological Innovations in Diaphragm Metering Pumps at the 138th China Import and Export Fair

At the 138th China Import and Export Fair, the spotlight will shine on diaphragm metering pumps, showcasing key technological innovations that enhance efficiency in fluid handling applications. According to industry reports, the market for diaphragm pumps is projected to grow at a CAGR of approximately 5% from 2023 to 2030, driven by their versatility in various sectors such as chemicals, food & beverage, and pharmaceuticals. The fair, with over 32,000 participating enterprises, provides an ideal platform for manufacturers to introduce these cutting-edge technologies.

Innovations in diaphragm metering pumps include advancements in materials and integration of smart technology for precise flow control. The introduction of smart sensors and IoT capabilities allows for real-time monitoring and advanced diagnostics, significantly improving operational reliability and reducing maintenance costs. As global industries increasingly prioritize sustainability and efficiency, diaphragm metering pumps represent a significant step forward, aligning with the fair's theme of innovation and making a strong case for the potential of these devices in modern manufacturing.

Market Trends and Consumer Demands Influencing Diaphragm Metering Pumps

The diaphragm metering pumps market is witnessing significant growth driven by evolving consumer demands and market trends. According to a recent report by MarketsandMarkets, the global diaphragm pump market is estimated to reach USD 4.7 billion by 2027, growing at a CAGR of 5.6% from 2022. This trajectory is largely influenced by industries emphasizing precision and reliability in fluid management, with the chemical and wastewater treatment sectors being prominent consumers. As industries strive for sustainability and efficiency, the demand for advanced diaphragm metering pumps that offer accurate dosing and minimal leakage is increasing.

Moreover, the rising trend of automation in manufacturing processes is shaping the future of diaphragm metering pumps. A report from ResearchAndMarkets highlights that automated systems improve operational efficiency and reduce human error, leading to higher adoption rates of diaphragm pumps. Additionally, the emphasis on reducing environmental impact is pushing manufacturers to innovate and develop more energy-efficient and eco-friendly diaphragm pumps. This shift not only meets consumer expectations but also aligns with regulatory requirements aimed at minimizing the ecological footprint of industrial operations. As seen at the 138th China Import and Export Fair in 2025, leading companies are showcasing cutting-edge technology in diaphragm metering pumps, indicative of a robust market responding effectively to these growing trends.

Sustainability and Efficiency: The Role of Diaphragm Metering Pumps in Modern Industries

At the 138th China Import and Export Fair 2025, diaphragm metering pumps are set to showcase their significant contribution to sustainability and efficiency within modern industries. These pumps are designed to deliver precise fluid handling, making them an ideal choice for applications that demand accurate dosing. Their ability to operate with minimal energy consumption not only reduces operating costs but also aligns with the growing demand for eco-friendly solutions across industries. As manufacturers strive to meet environmental regulations, diaphragm metering pumps stand out for their reliability and performance.

Tip: When selecting a diaphragm metering pump, consider the materials of construction that are compatible with the chemicals being pumped. This choice can reduce degradation and enhance the lifespan of the pump, leading to increased sustainability.

Moreover, the versatility of diaphragm metering pumps makes them suitable for a range of industries, including water treatment, pharmaceuticals, and food processing. Their innovative design ensures minimal leak risk, which is crucial for maintaining product integrity and meeting safety standards. As industries increasingly prioritize sustainability, incorporating diaphragm metering pumps can significantly bolster efforts to enhance operational efficiency while minimizing environmental impact.

Tip: Regular maintenance of diaphragm metering pumps is key to ensuring long-term efficiency and environmental compliance. Implementing a preventive maintenance schedule can help identify potential issues before they escalate, thereby ensuring optimal performance.

Networking Opportunities at the 138th China Import and Export Fair for Diaphragm Pump Manufacturers

The 138th China Import and Export Fair in 2025 presents a significant opportunity for diaphragm pump manufacturers to connect and collaborate. This event serves as a crucial networking platform, bringing together industry players from around the globe. Manufacturers can establish valuable relationships with suppliers, distributors, and potential customers, facilitating knowledge exchange and fostering strategic partnerships that can lead to innovative product development and market expansion.

In addition to networking, the fair will feature discussions and workshops focused on advancements in diaphragm metering pump technology. Participants will have the chance to engage with industry experts and gain insights into the latest trends and challenges facing the sector. These interactions not only enhance business prospects but also contribute to the overall growth of the diaphragm pump market. The collaboration fostered at the fair ensures that manufacturers remain competitive and responsive to evolving customer needs and technological advancements.

Related Posts

-

What Makes Plunger Metering Pump Essential for Precision Fluid Control

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

How to Select the Right Chemical Metering Pump for Your Application

-

5 Best Chemical Pumps for Efficient Industrial Use

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

5 Innovative Ways Pressure Pumps Enhance Industrial Efficiency