Blog

- Home

- Blog

Understanding the Importance of High Pressure Dosing Pumps in Modern Industries

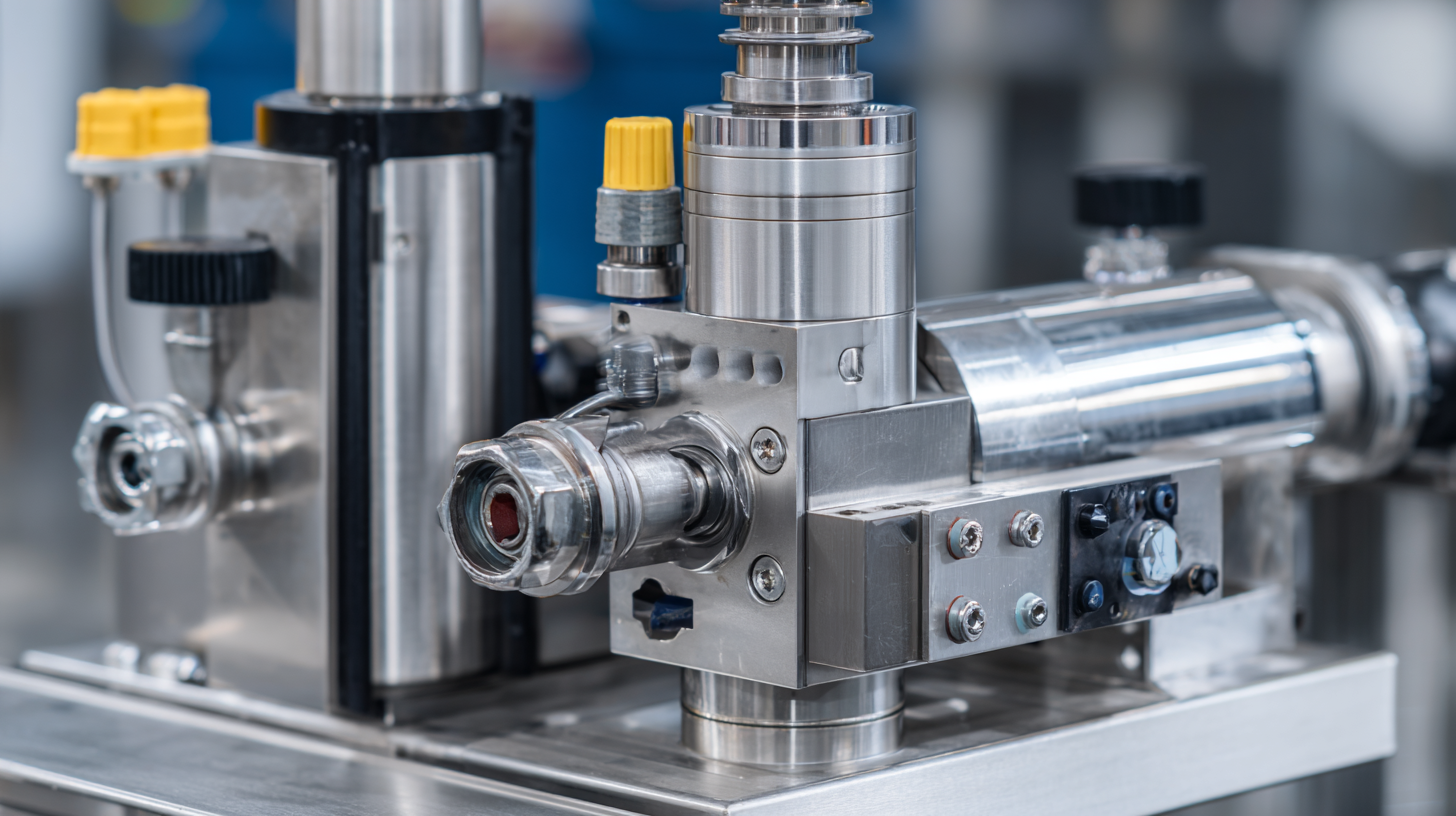

In contemporary industrial applications, the significance of the High Pressure Dosing Pump cannot be overstated. These pumps are engineered to deliver precise fluid metering under high pressure, which is crucial in sectors such as water treatment, pharmaceuticals, and chemical processing. According to a report by MarketsandMarkets, the global dosing pump market is projected to reach USD 6.9 billion by 2026, driven by an increasing demand for accurate dosing solutions.

Furthermore, the demand for High Pressure Dosing Pumps is being propelled by stringent regulations regarding chemical dosing levels and the need for enhanced operational efficiency. Their ability to maintain consistency and reliability in high-pressure environments makes them indispensable for modern production processes, ultimately leading to optimized resource utilization and reduced operational costs. As industries evolve, the reliance on High Pressure Dosing Pumps is expected to grow, highlighting their pivotal role in enhancing process effectiveness and safety.

The Role of High Pressure Dosing Pumps in Enhancing Process Efficiency Across Industries

High pressure dosing pumps play a critical role in enhancing process efficiency across various industries, including pharmaceuticals, chemical manufacturing, and water treatment. According to a 2021 report by TechSci Research, the global dosing pump market is projected to grow at a CAGR of 6.8% from 2021 to 2026, driven by increased demand for precise dosing solutions. These pumps are engineered to deliver fluids at high pressures and accuracy, ensuring that processes can be completed more reliably and with minimal waste. This efficiency not only reduces operational costs but also minimizes environmental impact by allowing for more controlled use of hazardous chemicals.

Tips for choosing the right high pressure dosing pump include considering the nature of the fluids being pumped—viscous or corrosive materials may require specialized pumps with specific materials. Additionally, it is essential to evaluate the required flow rates and pressures to ensure optimal performance within the system. Regular maintenance and timely calibration of these pumps are vital, as failure to do so can lead to fluctuations in dosing accuracy and overall system efficiency.

Incorporating high pressure dosing pumps can significantly enhance production rates and product quality. By enabling precise control over dosing, these pumps help industries maintain compliance with regulatory standards, ultimately leading to improved customer satisfaction and competitive advantage in the marketplace. Investing in the right dosing technology can prove to be a game-changer for companies seeking to optimize their processes and reduce waste.

Key Industry Applications of High Pressure Dosing Pumps: From Water Treatment to Chemical Manufacturing

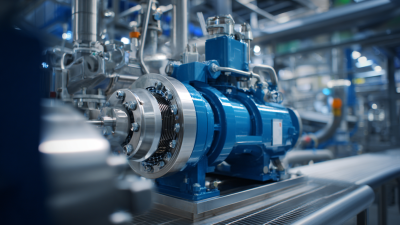

High pressure dosing pumps play a critical role in various industries, particularly in water treatment and chemical manufacturing. In water treatment processes, these pumps ensure precise dosing of chemicals needed for disinfection and purification, which is essential for maintaining safe drinking water standards. This accuracy helps in achieving optimal treatment results while minimizing chemical waste, thus enhancing overall operational efficiency.

In the realm of chemical manufacturing, high pressure dosing pumps are instrumental in the transportation and injection of viscous fluids and aggressive chemicals. Their ability to operate under high pressures allows for the efficient handling of reactive substances, ensuring that production processes run smoothly. As industries increasingly prioritize sustainability and efficiency, the demand for high pressure dosing pumps is expected to grow. The global dosing pump market is projected to increase from $6.35 billion in 2025 to $9.06 billion by 2032, reflecting a compound annual growth rate of 5.21% during the forecast period. This growth underscores the vital importance of these pumps in meeting the evolving needs of modern industrial applications.

Understanding the Importance of High Pressure Dosing Pumps in Modern Industries

| Industry Application | Purpose | Dosing Pressure (psi) | Flow Rate (L/h) |

|---|---|---|---|

| Water Treatment | Chemical dosing for purification | 150-300 | 500-2000 |

| Chemical Manufacturing | Precise chemical blending | 200-400 | 300-1500 |

| Food and Beverage | Additives and flavoring | 50-150 | 100-1000 |

| Pharmaceuticals | Active ingredient dosing | 100-200 | 200-800 |

| Industrial Cleaning | Chemical agents for cleaning | 100-250 | 400-1600 |

Critical Performance Metrics: Understanding Flow Rates and Pressure Levels in Dosing Pumps

In modern industries, high pressure dosing pumps play a crucial role in various applications, from chemical manufacturing to water treatment. The effectiveness of these pumps is often evaluated through critical performance metrics such as flow rates and pressure levels. According to a report from Grand View Research, the global dosing pump market size is expected to reach $6.5 billion by 2025, highlighting the growing importance of precise flow control in industrial processes.

Flow rates indicate the volume of fluid delivered per unit time, which is essential for maintaining accuracy in dosing operations. Modern dosing pumps are capable of delivering flow rates ranging from a few milliliters per hour to several hundred liters per hour, depending on the application. An industry report by Technavio specifies that the demand for dosing pumps with high flow rates is on the rise in sectors such as pharmaceuticals and food processing, where precise ingredient measurements directly impact product quality and safety.

Pressure levels are equally vital, as they determine the pump’s ability to overcome system resistance and deliver fluids at required rates. High pressure dosing pumps commonly operate within a range of 10 to 150 bar, ensuring efficient transportation of viscous and corrosive liquids. A study published in the Journal of Fluid Mechanics indicates that maintaining optimal pressure levels not only enhances dosing accuracy but also extends pump lifespan by reducing wear and tear. This correlation between pressure management and operational longevity further cements the significance of high pressure dosing pumps in contemporary industrial practices.

Understanding Flow Rates and Pressure Levels in Dosing Pumps

Impact of High Pressure Dosing Pumps on Sustainability and Environmental Compliance Efforts

High pressure dosing pumps play a crucial role in modern industries, particularly when it comes to enhancing sustainability and ensuring environmental compliance. According to a report by the Environmental Protection Agency (EPA), precise dosing and mixing of chemicals can lead to a reduction in hazardous waste generation by up to 30%. This reduction not only mitigates environmental impact but also helps companies adhere to increasingly stringent regulations regarding waste management and emissions.

High pressure dosing pumps play a crucial role in modern industries, particularly when it comes to enhancing sustainability and ensuring environmental compliance. According to a report by the Environmental Protection Agency (EPA), precise dosing and mixing of chemicals can lead to a reduction in hazardous waste generation by up to 30%. This reduction not only mitigates environmental impact but also helps companies adhere to increasingly stringent regulations regarding waste management and emissions.

Moreover, high pressure dosing pumps contribute to energy efficiency—a vital element in sustainable practices. A study by the International Energy Agency (IEA) highlights that optimized dosing systems can decrease energy consumption by 15-20%. This is particularly significant in sectors such as pharmaceuticals and water treatment, where precise chemical injection is necessary for both operational efficiency and regulatory compliance. By leveraging advanced pump technologies, industries are moving towards greener practices while maintaining productivity and safety standards.

Emerging Technologies in High Pressure Dosing Pumps: Innovations Driving Industry Growth and Efficiency

Emerging technologies in high pressure dosing pumps play a crucial role in propelling industry growth and enhancing operational efficiency. Advanced materials and smart design techniques have improved the durability and performance of these pumps. Innovations such as real-time monitoring sensors and automated control systems have not only minimized human error but also optimized the dosing process, ensuring the precise delivery of fluids in various applications, from chemical manufacturing to food processing.

Furthermore, the integration of IoT (Internet of Things) capabilities allows for remote monitoring and predictive maintenance, which significantly reduces downtime and maintenance costs. Companies can now leverage data analytics to anticipate failures and streamline operations, leading to increased productivity. The move towards more energy-efficient models and environmentally friendly materials also aligns with global sustainability goals, making high pressure dosing pumps essential for modern industries seeking to balance performance with ecological responsibility.

These advancements are transforming traditional practices, positioning high pressure dosing pumps at the forefront of industrial innovation.

Related Posts

-

Unlocking Efficiency: The Significant Advantages of Plunger Metering Pumps in Process Industries

-

Ultimate Guide to Selecting the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

Exploring Plunger Metering Pump Innovations at the 2025 China Import and Export Fair

-

Transforming the Future: The Role of Industrial Dosing Pumps at China’s 138th Canton Fair 2025

-

Unlocking Efficiency: How High Pressure Pumps Revolutionize Industrial Processes

-

5 Innovative Ways Pressure Pumps Enhance Industrial Efficiency