Blog

- Home

- Blog

Exploring the Innovations in Industrial Pumps: How Cutting-Edge Technology is Revolutionizing Efficiency

In recent years, the Industrial Pumps sector has undergone a remarkable transformation, driven by technological advancements that are redefining efficiency and productivity standards across various industries. According to a report by MarketsandMarkets, the global industrial pumps market is projected to reach $88.7 billion by 2025, growing at a CAGR of 5.9% from 2020. This surge is largely attributed to the integration of digital technologies, such as IoT and AI, which enhance operational reliability and predictive maintenance capabilities. Furthermore, a study from Frost & Sullivan highlights that these innovations lead to energy savings of up to 30%, underscoring their critical role in addressing sustainability challenges. As organizations strive to optimize their processes, the evolution of industrial pumps emerges as a key factor in driving operational efficiency and reducing energy consumption, setting the stage for a future where smart pumping solutions become standard across the industry.

Revolutionizing Efficiency: A Deep Dive into Smart Pump Technologies

The advent of smart pump technologies is transforming industries by enhancing operational efficiency and reducing costs. These innovative systems utilize advanced sensors and real-time data analytics to monitor pump performance and diagnose issues proactively. This capability not only extends the lifespan of the equipment but also minimizes downtime, allowing businesses to operate seamlessly. By harnessing the power of the Internet of Things (IoT), smart pumps can communicate with other connected devices, providing a holistic view of the entire system and enabling predictive maintenance.

Moreover, energy efficiency is a significant focus of these technologies. Smart pumps can automatically adjust their output based on demand, optimizing power consumption and reducing energy waste. This adaptability is crucial in industries where energy costs are a major concern. Additionally, the integration of artificial intelligence further streamlines operations, as machine learning algorithms can analyze historical performance data to predict future trends and adjust settings accordingly. As industries embrace these cutting-edge innovations, the potential for increased productivity and sustainability becomes not just achievable but inevitable.

Exploring the Innovations in Industrial Pumps: How Cutting-Edge Technology is Revolutionizing Efficiency

| Technology | Efficiency Improvement (%) | Usage Type | Key Features |

|---|---|---|---|

| Smart Control Systems | 25% | Industrial | Real-time monitoring, predictive maintenance |

| Variable Frequency Drives (VFD) | 30% | Water Treatment | Energy savings, improved water flow control |

| Magnetic Drive Pumps | 20% | Chemical Processing | Leak-free operation, efficiency in handling corrosive fluids |

| IoT-Enabled Pumps | 35% | Energy Sector | Remote monitoring, data analytics |

| Self-Priming Pumps | 15% | Construction | Ease of use, reduced labor costs |

Integrating IoT and AI: The Future of Industrial Pump Systems

The integration of IoT (Internet of Things) and AI (Artificial Intelligence) is transforming the landscape of industrial pump systems, offering unprecedented levels of efficiency and control. These cutting-edge technologies enable real-time monitoring, predictive maintenance, and automated adjustments based on operational data. For instance, IoT sensors can track variables such as flow rates, pressure levels, and energy consumption, allowing operators to optimize performance proactively and reduce downtime.

**Tip:** Implementing a smart monitoring system can significantly enhance the reliability of your pump operations. Regularly assess the data collected by IoT devices to identify patterns that may indicate potential issues before they escalate.

Additionally, AI algorithms can analyze vast amounts of data to provide actionable insights, predicting failures before they occur. This not only saves costs associated with emergency repairs but also extends the lifespan of the pump systems. By adopting such intelligent solutions, industries can maintain optimal performance, ensuring that processes run smoothly and efficiently.

**Tip:** When integrating AI solutions, ensure that your team is trained to interpret and act on the insights generated. This human-AI collaboration can lead to more informed decision-making and further improvements in operational efficiency.

Sustainability in Pump Design: Innovations in Energy Consumption

In today's rapidly evolving industrial landscape, sustainability has become a cornerstone of pump design. Innovative engineering principles are prioritizing energy efficiency, with the latest reports indicating that modern pumps can achieve energy savings of up to 30% compared to traditional models. This is largely thanks to advancements in materials and smart technologies, such as Internet of Things (IoT) integration, which allows for real-time monitoring and optimization of pump operations. According to a study by the Hydraulic Institute, the right pump configuration can reduce energy waste and lower operational costs significantly, making a profound impact on both the environment and a company’s bottom line.

Tips: When selecting a pump, consider those designed with variable frequency drives (VFDs), which adjust motor speed based on demand and can further enhance energy savings. Additionally, regular maintenance of pumps not only extends their lifespan but also ensures they operate at peak efficiency, reducing unnecessary energy consumption.

As manufacturers strive for greener solutions, the adoption of eco-friendly materials and design methods is becoming prevalent. Reports suggest that integrating renewable energy sources can complement pump operations, leading to a more sustainable process overall. By focusing on these innovations, industries not only comply with environmental standards but also address the growing societal demand for responsible production practices.

The Role of Advanced Materials in Enhancing Pump Performance

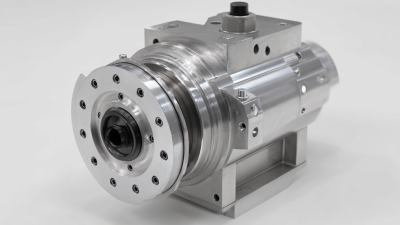

The advent of advanced materials in the manufacturing of industrial pumps has significantly transformed their efficiency and reliability. Traditional materials often struggled with wear and corrosion, leading to frequent maintenance and replacement. However, innovations such as composite materials, ceramics, and specialized alloys have emerged, dramatically enhancing the performance of pumps. These modern materials not only provide better resistance to harsh chemicals and extreme temperatures but also contribute to weight reduction and increased durability.

Moreover, the integration of advanced materials has a direct impact on energy efficiency. Lightweight components require less energy for operation, translating into lower operational costs. Additionally, these materials allow for smoother flow dynamics, minimizing turbulence and maximizing throughput. As industries seek to achieve higher performance standards and sustainability targets, the role of advanced materials in pump technology becomes increasingly crucial, paving the way for more efficient and environmentally friendly operations.

Innovations in Industrial Pumps: Efficiency Revolution

Case Studies: Successful Implementation of Innovative Pump Solutions

The industrial pump sector has witnessed remarkable transformations through the adoption of innovative technologies. A pivotal aspect of this evolution is evident in the case studies highlighting successful implementations of advanced pump solutions. For instance, a recent report by the Global Pump Market Analysis predicts that the sector will reach a value of $69.9 billion by 2025, showcasing an annual growth rate of 5.2%. Companies that have embraced cutting-edge technologies, such as IoT-enabled pumps, have reported efficiency improvements of up to 30% in energy consumption and maintenance costs.

One prominent example can be seen in the chemical manufacturing industry, where the integration of advanced data analytics and remote monitoring has drastically reduced downtime. In a notable case, a leading chemical company employed smart pumps equipped with predictive maintenance tools. This shift not only resulted in a 25% decrease in operational costs but also enhanced product quality and safety. Such innovations demonstrate that investing in technology is not merely a trend but a necessary step toward achieving sustainable operational efficiency in the increasingly competitive industrial landscape.

Related Posts

-

7 Best Industrial Pumps You Should Consider for Your Next Project

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

Understanding the Benefits of High Flow Hydraulic Pump in Modern Industrial Applications

-

5 Essential Tips for Sourcing the Best Pump Water Solutions Globally

-

Innovative Solutions for Plunger Metering Pump Applications

-

How to Optimize Pump Water Efficiency for Sustainable Resource Management