Blog

- Home

- Blog

Exploring the Latest Innovations in Pump Products for Efficient Fluid Management

In the fast-evolving world of fluid management, the innovations in pump products are critical to enhancing efficiency and sustainability. As industry expert Dr. Emily Carter, a renowned fluid dynamics engineer, states, “The future of pump products lies in leveraging advanced technologies to minimize energy consumption while maximizing performance.” This insight underscores the growing importance of adopting cutting-edge solutions to meet the increasing demands for effective fluid management across various sectors.

Emerging trends such as smart pump systems, improved materials, and energy-efficient designs are transforming how industries approach fluid handling. These innovations not only promise to optimize operational efficiency but also contribute to significant cost savings and reduced environmental impact. By harnessing the latest technologies, businesses can ensure they remain competitive while adhering to rigorous sustainability goals.

As we delve into this exploration of the latest innovations in pump products, we will examine the mechanisms behind these advancements, their implications for different industries, and the best practices for implementation. Join us in uncovering how these new developments are shaping the future of fluid management and redefining operational standards across the board.

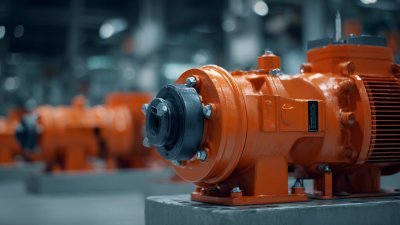

Revolutionary Pump Designs Enhancing Fluid Efficiency in Various Industries

Recent advancements in pump design have significantly enhanced fluid efficiency across various industries, from water treatment to chemical processing. According to a report by Research and Markets, the global pump market is projected to grow from $77 billion in 2022 to $97 billion by 2028, reflecting an increasing demand for more efficient fluid management solutions. Innovative features such as magnetic drive technology and smart sensors are revolutionizing traditional pump systems, allowing for improved energy efficiency and reduced operational costs.

One of the notable trends is the incorporation of IoT (Internet of Things) capabilities into pump products. This integration allows for real-time monitoring and predictive maintenance, minimizing downtime and maximizing performance. A study by the International Journal of Advanced Manufacturing Technology highlights that smart pumps can enhance energy efficiency by up to 30%, which is a critical factor as industries strive to meet sustainability goals. Furthermore, advanced materials, such as ceramics and composite materials, are being employed to reduce wear and tear, resulting in longer lifespan and efficiency of these pumps. These innovations represent a paradigm shift in fluid management, enabling industries to operate more sustainably and economically.

Smart Pump Technologies: Integrating IoT for Remote Monitoring and Control

The integration of Internet of Things (IoT) technology into pump systems is revolutionizing fluid management, offering unprecedented capabilities for remote monitoring and control. According to a report by MarketsandMarkets, the IoT-enabled pumps market is expected to grow from $2.8 billion in 2020 to $6.8 billion by 2025, at a compound annual growth rate (CAGR) of 19.5%. This surge is attributed to the increasing need for automation and real-time data analytics in industrial processes, facilitating not only operational efficiency but also improved energy management.

Smart pump technologies enable operators to monitor performance metrics such as flow rates, pressure levels, and energy consumption from anywhere, at any time. By harnessing data analytics, companies can preemptively identify maintenance needs, significantly reducing downtime and operational costs. A study from Siemens revealed that predictive maintenance strategies, enabled by IoT, can reduce maintenance costs by up to 30% and increase asset life by 20-40%. As industries continue to embrace digital transformation, integrating smart pump technologies will be crucial in enhancing fluid management processes, optimizing resource usage, and promoting sustainability in operations.

Smart pump technologies enable operators to monitor performance metrics such as flow rates, pressure levels, and energy consumption from anywhere, at any time. By harnessing data analytics, companies can preemptively identify maintenance needs, significantly reducing downtime and operational costs. A study from Siemens revealed that predictive maintenance strategies, enabled by IoT, can reduce maintenance costs by up to 30% and increase asset life by 20-40%. As industries continue to embrace digital transformation, integrating smart pump technologies will be crucial in enhancing fluid management processes, optimizing resource usage, and promoting sustainability in operations.

Eco-Friendly Pump Materials: Driving Sustainable Fluid Management Solutions

The development of eco-friendly pump materials is crucial for enhancing sustainable fluid management solutions. With increasing environmental awareness and stringent regulations, industries are seeking alternatives to conventional pump materials that often have detrimental environmental impacts. Innovations such as bioplastics and recycled metals are paving the way for more sustainable practices. These materials not only reduce the carbon footprint of manufacturing processes but also promote circular economy principles by incorporating recycled content.

The development of eco-friendly pump materials is crucial for enhancing sustainable fluid management solutions. With increasing environmental awareness and stringent regulations, industries are seeking alternatives to conventional pump materials that often have detrimental environmental impacts. Innovations such as bioplastics and recycled metals are paving the way for more sustainable practices. These materials not only reduce the carbon footprint of manufacturing processes but also promote circular economy principles by incorporating recycled content.

Furthermore, the integration of advanced technologies in the design and production of these eco-friendly pumps enhances their efficiency and functionality. For instance, the use of smart technology in monitoring pump performance can optimize operations, reducing waste and energy consumption. As companies continue to adopt green materials and innovative engineering solutions, the potential for reduced environmental impact and improved resource management becomes significantly greater. This shift not only meets the growing demand for sustainability but also positions businesses as leaders in the transition towards a greener economy.

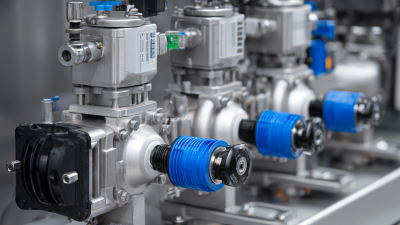

Advanced Pump Control Systems: Optimizing Performance and Reducing Downtime

The advancement of pump control systems is revolutionizing fluid management across various industries. With the integration of smart technologies, these systems enhance the performance of pumps by optimizing their operational parameters in real-time. This innovation not only boosts efficiency but also plays a critical role in reducing downtime, ensuring that processes remain uninterrupted. The use of predictive maintenance algorithms allows operators to foresee potential failures, which can drastically minimize unexpected outages and maintenance costs.

**Tips:** To maximize the benefits of advanced pump control systems, consider regularly updating your software and hardware. Implementing a robust data analytics platform can also help in tracking performance metrics, thereby facilitating informed decision-making regarding maintenance schedules and operational adjustments.

By utilizing these cutting-edge control systems, companies can achieve greater energy efficiency, translating into both operational savings and a lower environmental impact. As more industries adopt these technologies, the potential for improved fluid management and reduced operational risks continues to expand.

**Tips:** Training your staff on the new control technologies ensures they are equipped to handle troubleshooting and optimization tasks effectively, further enhancing system reliability and performance.

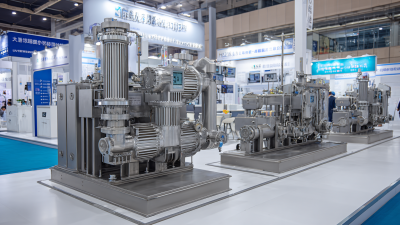

Trends in Magnetic Drive Pumps: A Quiet and Efficient Alternative

Magnetic drive pumps have emerged as a revolutionary solution in fluid management, particularly renowned for their quiet operation and high efficiency. Unlike traditional pumps that rely on mechanical seals, magnetic drive pumps utilize a magnetic coupling to transfer torque from the motor to the impeller, minimizing leakage risks and enhancing durability. This innovation not only reduces the noise typically produced during pumping but also significantly lowers energy consumption, making these pumps an ideal choice for a variety of industrial applications where both performance and quiet operation are crucial.

Tips: When selecting a magnetic drive pump, it is essential to consider the fluid characteristics, such as viscosity and temperature, to ensure compatibility and optimal performance. Additionally, regular maintenance checks can help prolong the lifespan of the pump and maintain its operational efficiency.

The market trend indicates a growing preference for magnetic drive pumps, particularly in sectors that require stringent safety standards and minimal environmental impact. As industries increasingly focus on sustainability, these pumps align perfectly with eco-friendly practices by reducing energy use and leakage. Investing in magnetic drive technology not only enhances operational efficiency but also contributes to a greener future in fluid management.

Exploring the Latest Innovations in Pump Products for Efficient Fluid Management - Trends in Magnetic Drive Pumps: A Quiet and Efficient Alternative

| Feature | Magnetic Drive Pump 1 | Magnetic Drive Pump 2 | Magnetic Drive Pump 3 |

|---|---|---|---|

| Max Flow Rate (GPM) | 30 | 25 | 20 |

| Max Head (Feet) | 150 | 120 | 100 |

| Power Consumption (HP) | 0.75 | 0.5 | 0.33 |

| Noise Level (dB) | 55 | 50 | 48 |

| Material | Stainless Steel | Polypropylene | PVDF |

| Price ($) | 1200 | 950 | 700 |

Related Posts

-

Top Strategies for Sourcing High Performance Industrial Pumps Globally

-

Exploring the Innovations in Industrial Pumps: How Cutting-Edge Technology is Revolutionizing Efficiency

-

Exploring the Latest Innovations in Pump Products: Enhancing Efficiency and Sustainability

-

8 Key Advantages of Diaphragm Pumps: Efficiency and Reliability in Fluid Management

-

Innovative Solutions for Plunger Metering Pump Applications

-

Exploring the Impact of Diaphragm Metering Pumps at the 138th China Import and Export Fair 2025