Blog

- Home

- Blog

8 Key Advantages of Diaphragm Pumps: Efficiency and Reliability in Fluid Management

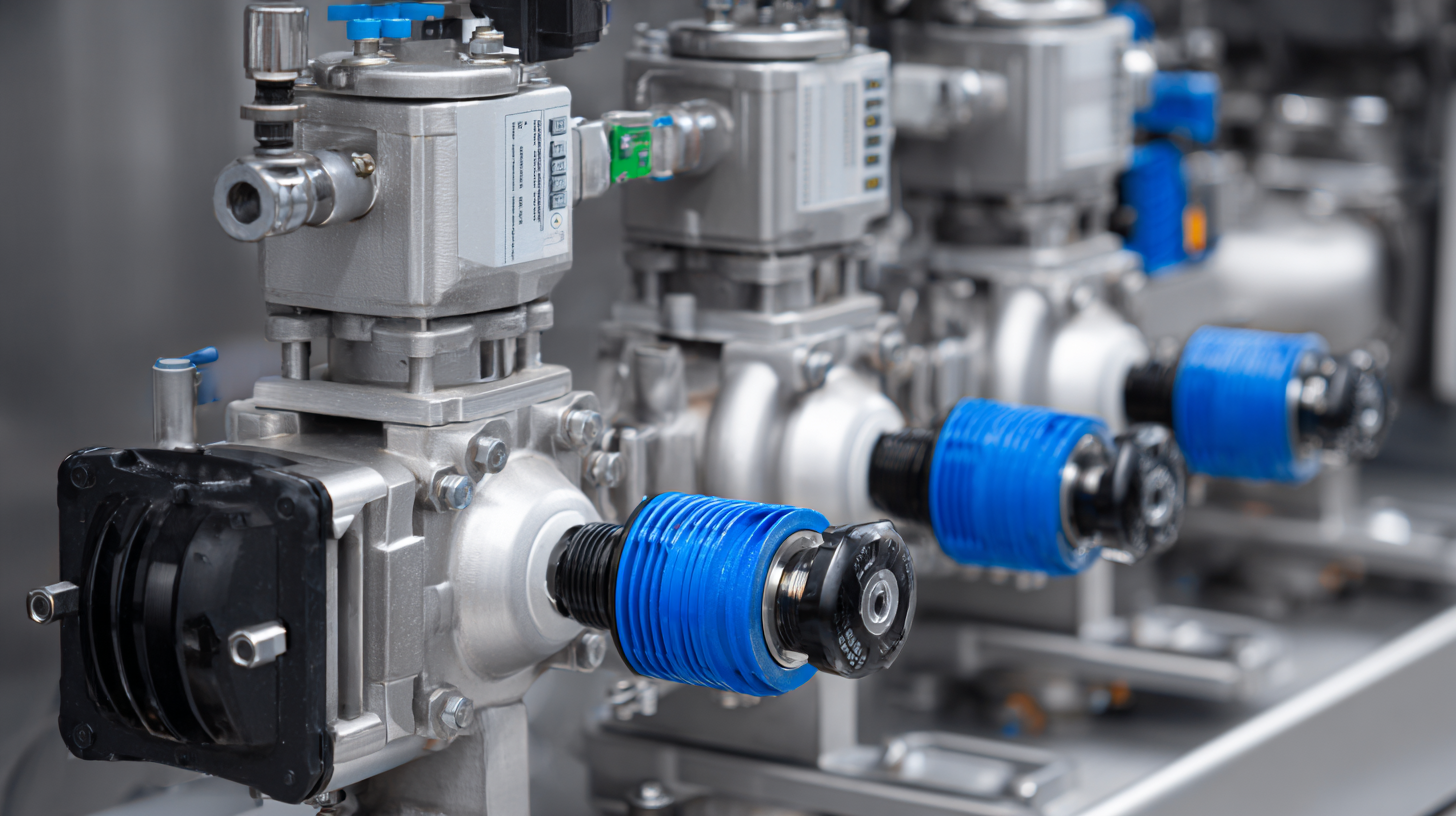

In the realm of fluid management, Diaphragm Pumps have emerged as a pivotal technology, offering an impressive array of benefits that enhance both efficiency and reliability. These pumps, recognized for their unique design and operational capabilities, play a crucial role in various industrial applications—from chemical processing to food and beverage production. With their ability to handle viscous fluids, solids-laden liquids, and aggressive chemicals, Diaphragm Pumps stand out for their versatility and durability.

This article delves into the eight key advantages of Diaphragm Pumps, highlighting how these features not only improve operational performance but also contribute to cost savings and enhanced safety in fluid handling systems. By understanding the strengths of Diaphragm Pumps, industries can make informed decisions that drive productivity and ensure streamlined processes in their fluid management strategies.

Key Features that Enhance the Efficiency of Diaphragm Pumps

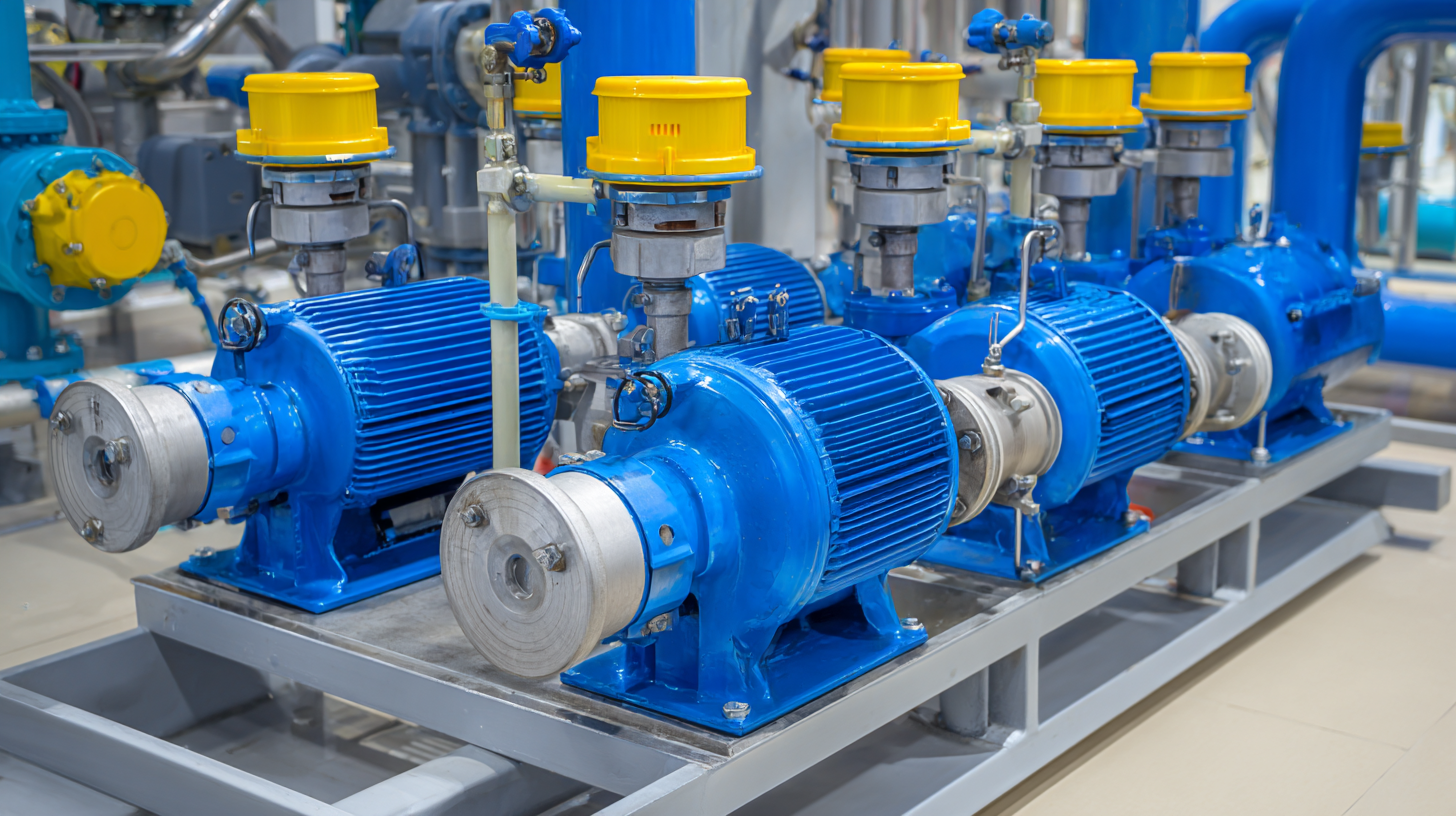

Diaphragm pumps are increasingly recognized for their efficiency and reliability in fluid management, particularly due to their unique features that enhance performance. One of the key advantages is their ability to handle a wide variety of fluids, including corrosive and viscous materials, without compromising on effectiveness. This versatility makes them suitable for diverse industries, from agriculture to wastewater treatment. Additionally, diaphragm pumps operate with minimal moving parts, which not only reduces wear and tear but also leads to lower maintenance costs and downtime.

Diaphragm pumps are increasingly recognized for their efficiency and reliability in fluid management, particularly due to their unique features that enhance performance. One of the key advantages is their ability to handle a wide variety of fluids, including corrosive and viscous materials, without compromising on effectiveness. This versatility makes them suitable for diverse industries, from agriculture to wastewater treatment. Additionally, diaphragm pumps operate with minimal moving parts, which not only reduces wear and tear but also leads to lower maintenance costs and downtime.

Another significant feature contributing to the efficiency of diaphragm pumps is their self-priming capability. This allows them to draw fluids into the system without the need for additional assistance, enhancing operational reliability. Furthermore, the design of diaphragm pumps minimizes pulsation, ensuring a smoother flow rate. This characteristic is particularly valuable in applications where consistent pressure is crucial. Overall, the combination of these features positions diaphragm pumps as a prime choice for effective fluid management in various sectors.

How Diaphragm Pumps Ensure Consistent Fluid Handling Reliability

Diaphragm pumps are renowned for their unparalleled reliability in fluid management, making them a preferred choice for various industrial applications. The unique design of diaphragm pumps allows them to handle a wide range of fluids, including corrosive and viscous materials, without compromising on safety or performance. This capability ensures that operators can rely on these pumps for consistent fluid handling, minimizing the risk of leaks or contamination. The diaphragm mechanism creates a seal that effectively isolates the fluid from the pump's internal components, enhancing reliability and reducing maintenance needs.

Moreover, diaphragm pumps are equipped to deliver precise flow rates while maintaining high efficiency. This consistent performance is crucial for industries where fluid accuracy is paramount, such as pharmaceuticals and food processing. Their ability to operate in diverse environments and adapt to varying pressure conditions further solidifies their role in fluid management. As industries continue to prioritize efficiency alongside safety, diaphragm pumps stand out as a robust solution for ensuring seamless fluid handling operations.

Energy Savings: The Cost-Effectiveness of Using Diaphragm Pumps

Diaphragm pumps have gained significant traction in various industries due to their energy efficiency and reliability in fluid management. The North American Utility Pump Market is expected to witness notable growth, particularly in diaphragm pump applications within sectors such as dewatering and industrial waste management. According to recent industry analyses, the global market for diaphragm pumps, specifically double and single diaphragm types, is projected to expand significantly, reaching approximately $4.5 billion by 2033. This growth is driven by the increasing demand for energy-saving solutions in sectors like cardboard manufacturing and the effective handling of industrial waste heat.

One of the main advantages of diaphragm pumps lies in their cost-effectiveness, particularly concerning energy savings. As reported, these pumps can facilitate electricity-free recovery of industrial waste heat, effectively utilizing energy sources that would otherwise contribute to environmental concerns. Furthermore, innovations in pump technology, such as low pulsation design, have been shown to enhance efficiency and performance, making diaphragm pumps a preferred choice for fluid transfer applications. The continuous improvements in diaphragm pump technology symbolize a response to the growing need for sustainable and economical fluid management solutions in today's industrial landscape.

Maintenance Tips for Maximizing Diaphragm Pump Lifespan

Proper maintenance is crucial for maximizing the lifespan of diaphragm pumps, which are known for their efficiency and reliability in fluid management. Regular inspection is the first step in maintenance; operators should check for any signs of wear and tear, such as leaks or abnormal noises. Identifying these issues early can prevent more significant damage and ensure the pump operates smoothly. Additionally, ensuring that the pump is installed correctly and that all connections are secure helps maintain its performance and longevity.

Lubrication is another essential aspect of diaphragm pump maintenance. Regularly lubricating moving parts reduces friction and wear, leading to a longer operational life. It's also important to use the right type of lubricant recommended by the manufacturer to avoid adverse reactions that could affect pump materials. Lastly, cleaning the pump regularly to remove any debris or buildup inside can help maintain efficiency and prevent clogs, further extending the life of the diaphragm pump. Implementing these maintenance tips will not only enhance the pump's performance but also contribute to a more reliable fluid management system.

Applications Where Diaphragm Pumps Excel in Performance

Diaphragm pumps are highly efficient and reliable, making them an ideal choice for various applications across industries. One of the primary areas where diaphragm pumps excel is in the handling of corrosive and viscous fluids. Chemical processing plants frequently utilize these pumps to transfer hazardous materials safely, minimizing the risk of leaks and environmental contamination. Their ability to create a seal through diaphragm movement prevents backflow, ensuring consistent flow rates and reliable operation in demanding environments.

Tips for optimizing diaphragm pump performance include regular maintenance checks to identify wear and tear on diaphragms and seals, ensuring a longer lifespan and efficient operation. Additionally, selecting the right diaphragm material based on the fluid characteristics will significantly enhance pump performance. Applications in wastewater management and food processing also benefit from diaphragm pumps, as they can handle solids and slurries while maintaining hygiene and compliance with safety standards.

Another area where diaphragm pumps shine is in the pharmaceutical industry. Their precise flow control enables the accurate dosing of active ingredients, which is crucial for drug formulation. Employing diaphragm pumps in these sensitive applications not only boosts operational reliability but also ensures compliance with regulatory requirements.

8 Key Advantages of Diaphragm Pumps: Efficiency and Reliability in Fluid Management - Applications Where Diaphragm Pumps Excel in Performance

| Advantage | Description | Applications |

|---|---|---|

| High Efficiency | Diaphragm pumps maintain a high flow rate while consuming less energy. | Water treatment, chemical processing |

| Self-Priming | Can draw fluid into the pump without external assistance. | Pumping from underground sources, tanks |

| Versatile Fluid Handling | Handles a range of viscosities and particle-filled fluids. | Food and beverage processing, mining |

| Low Maintenance | Fewer moving parts lead to reduced wear and tear. | Industrial applications, agricultural sectors |

| Chemical Compatibility | Can be constructed from various materials to resist corrosion. | Chemical manufacturing, wastewater management |

| Safe Operation | Eliminates the risk of leaks and spills due to sealed design. | Pharmaceuticals, environmental labs |

| Variable Flow Control | Allows for precise adjustments in flow rates. | Oil and gas, construction |

| Portability | Lightweight and compact designs facilitate easy mobility. | Emergency response, mobile units |

Related Posts

-

How to Select the Right Chemical Metering Pump for Your Application

-

10 Tips for Maximizing Efficiency with High Pressure Hydraulic Pumps in Industrial Settings

-

How to Optimize Pump Water Efficiency for Sustainable Resource Management

-

How to Choose the Right Dosing Pump for Your Industrial Needs Based on Flow Rates and Chemical Compatibility

-

5 Essential Tips for Sourcing the Best Pump Water Solutions Globally

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications