Blog

- Home

- Blog

What Makes Plunger Metering Pump Essential for Precision Fluid Control

In the realm of fluid control, the significance of precision cannot be overstated, particularly in industries such as pharmaceuticals, chemicals, and food processing. According to a report by Research and Markets, the global metering pump market is projected to reach $4.5 billion by 2026, driven largely by the increasing demand for accurate and reliable liquid dispensing systems. Among various types of metering pumps, the Plunger Metering Pump stands out due to its ability to deliver precise flow rates even under varying pressures. This capability is essential in applications where exact dosing is critical, and it is further enhanced by advancements in automation and control technologies. As industries continue to emphasize efficiency and quality, the adoption of Plunger Metering Pumps is likely to grow, positioning them as a fundamental component for achieving optimal fluid management and operational excellence.

Understanding the Mechanism of Plunger Metering Pumps for Fluid Control

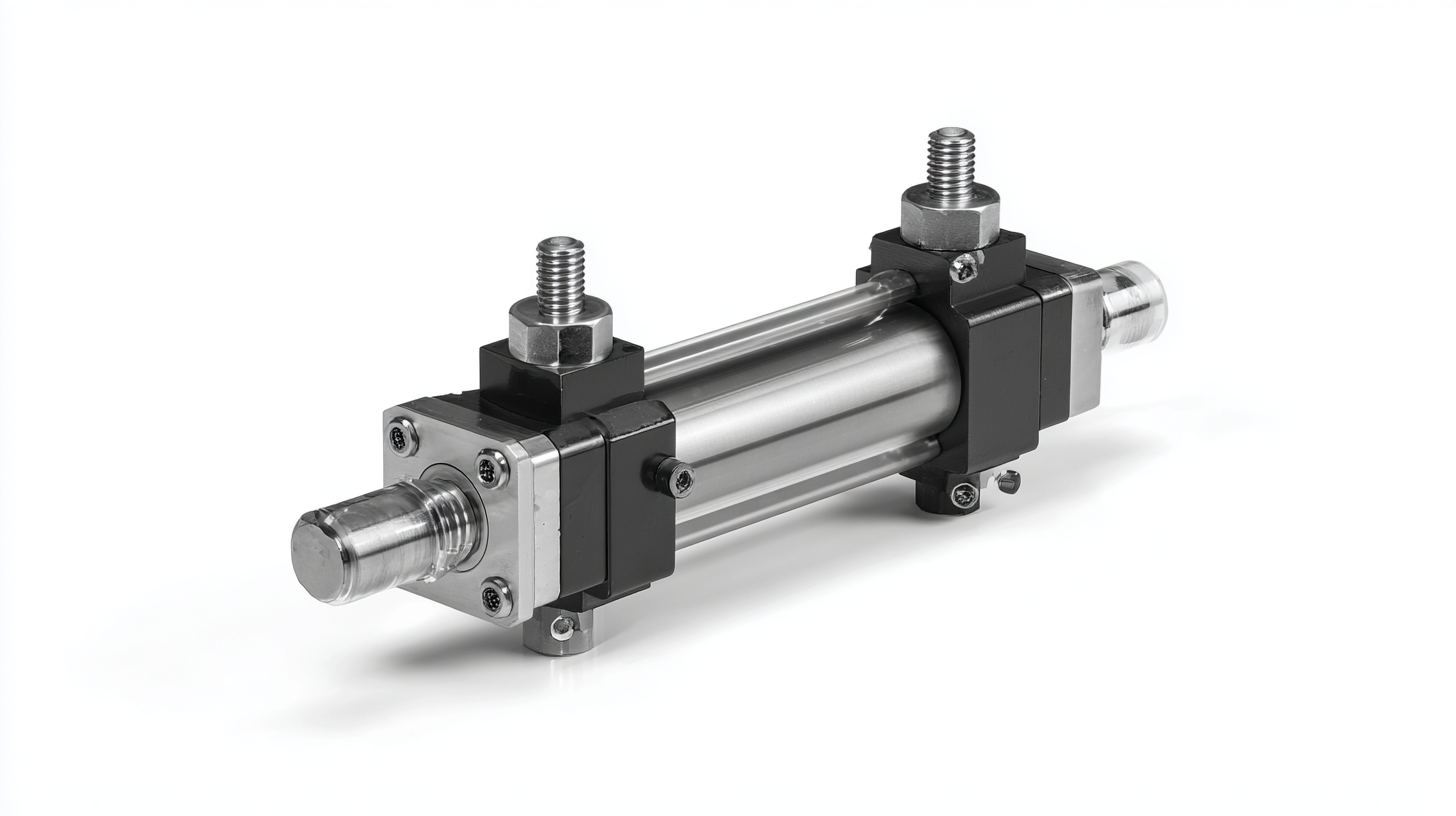

Plunger metering pumps play a crucial role in precision fluid control, essential for industries requiring accurate chemical dosing. These pumps operate based on the principle of positive displacement, utilizing a plunger to draw fluid into a chamber and then expelling it with calculated force. According to a report from the Fluid Measurement Industry Association, the accuracy of plunger metering pumps can reach up to 99.5%, making them suitable for applications in pharmaceuticals, petrochemicals, and food processing, where precision is paramount.

Plunger metering pumps play a crucial role in precision fluid control, essential for industries requiring accurate chemical dosing. These pumps operate based on the principle of positive displacement, utilizing a plunger to draw fluid into a chamber and then expelling it with calculated force. According to a report from the Fluid Measurement Industry Association, the accuracy of plunger metering pumps can reach up to 99.5%, making them suitable for applications in pharmaceuticals, petrochemicals, and food processing, where precision is paramount.

Understanding the mechanism involves recognizing that these pumps can handle a wide range of fluid viscosities and pressures while maintaining consistent flow rates. The design minimizes the risk of backflow, ensuring that the system delivers the exact amount of fluid needed, whether it’s a small quantity or a continuous supply. Reports indicate that these pumps can achieve flow rates from a few milliliters to several liters per minute, significantly enhancing operational efficiency.

Tip: To maintain optimal performance, regularly inspect seals and plunger surfaces for wear, and ensure appropriate lubrication is applied. Additionally, calibrate the pump periodically to ensure it continues to meet the specific dosing requirements of your application.

Key Advantages of Using Plunger Metering Pumps in Industrial Applications

Plunger metering pumps have emerged as a vital component in precision fluid control across various industrial applications. One of the key advantages of these pumps is their ability to deliver accurate and consistent flow rates, which is crucial in sectors such as chemical processing, pharmaceuticals, and water treatment. According to a report by Markets and Markets, the global metering pump market is projected to grow from USD 4.1 billion in 2020 to USD 5.3 billion by 2025, highlighting the rising demand for precise fluid handling solutions. This growth underscores the importance of metering pumps in optimizing process efficiency and reducing material wastage.

Additionally, plunger metering pumps are designed for durability and reliability, operating under high pressures while maintaining accuracy. The high repeatability of these pumps—often within ±1%—ensures that the right amount of fluid is delivered every time. In industries that experience stringent regulations, such as the pharmaceutical sector, this level of precision helps ensure compliance with quality and safety standards. The American Society for Testing and Materials (ASTM) has noted that inaccuracies in fluid handling can lead to significant financial losses and compromised product quality. Consequently, the adoption of plunger metering pumps is becoming increasingly essential for businesses aiming to enhance their operational efficiency and product integrity.

Selecting the Right Plunger Metering Pump for Your Specific Needs

When selecting the right plunger metering pump for your specific needs, it’s crucial to consider several factors that ensure optimal performance. The first step is to assess the type of fluid being pumped, as viscosity, temperature, and chemical compatibility will heavily influence the choice of materials and design specifications. Different applications may require pumps with unique features, such as adjustable flow rates or specific power requirements, making it essential to match the pump characteristics with your operational demands.

Additionally, evaluating the required accuracy and repeatability is vital when determining the right plunger metering pump. Precision is often critical in industries such as pharmaceuticals and food processing, where even slight deviations can lead to significant consequences. By understanding the specific flow rates and the necessary tolerances for your application, you can ensure that the selected pump will deliver the reliability and consistency required for impeccable fluid control. Furthermore, maintenance requirements and ease of operation should also be taken into account, as they can affect long-term performance and cost-effectiveness in your setup.

What Makes Plunger Metering Pump Essential for Precision Fluid Control

This chart illustrates the essential characteristics of plunger metering pumps, including flow rate, pressure, viscosity, temperature, and pulsation rate. These metrics are critical for ensuring precision fluid control in various applications.

Maintenance Tips for Enhancing the Longevity of Plunger Metering Pumps

Plunger metering pumps are critical for achieving precision fluid control in various applications, including hydraulic fracturing, where optimal fluid delivery can significantly impact production efficiency. To maintain the performance and longevity of these pumps, regular upkeep is essential. Key maintenance tips include routine inspection of critical components such as the pump head and seals, ensuring that they remain in good condition to avoid leaks and pressure drops.

Additionally, maintaining the air hose and pressure gauge is vital for accurate operation. A malfunction in these parts can lead to inefficient pumping and potentially costly downtime. Periodic lubrication of moving parts, as well as keeping the pump clean from debris, will further enhance its operational reliability. By following these maintenance practices, users can ensure that their plunger metering pumps continue to deliver precise fluid control, which is especially crucial in demanding applications like hydraulic fracturing.

Common Applications of Plunger Metering Pumps in Various Industries

Plunger metering pumps are widely utilized across various industries due to their precision and reliability in fluid control. One of the most common applications is in the chemical manufacturing sector, where accurate dosing of chemicals is crucial for product consistency and safety. These pumps allow for precise control of flow rates, ensuring the correct amount of chemicals is added during production processes, thereby minimizing waste and reducing operational costs.

Another significant application of plunger metering pumps is in water treatment facilities. They are employed to inject additives such as chlorine and other disinfectants into water systems. The ability to accurately meter these substances ensures effective purification while complying with environmental and safety regulations. Additionally, the pharmaceutical industry relies on plunger metering pumps for the precise delivery of active ingredients in formulations, ensuring product efficacy and patient safety. Their versatility and efficiency make them indispensable in maintaining high standards across these critical sectors.

Related Posts

-

Essential Insights: A Comprehensive Guide to Selecting Solenoid Metering Pumps for Your Applications

-

5 Essential Tips for Maximizing Performance of High Pressure Hydraulic Pumps

-

How to Select the Best Piston Pump for Your Industrial Needs

-

How to Choose the Right Hydraulic Pump for Your Industrial Needs

-

How to Choose the Right High Pressure Pump for Your Industrial Needs

-

How to Choose the Best Chemical Pumps for Your Industrial Needs