Blog

- Home

- Blog

How to Select the Right Chemical Metering Pump for Your Application

The selection of the right chemical metering pump is crucial for optimizing efficiency and ensuring safety in various industrial applications. According to a recent market research report by Mordor Intelligence, the global chemical metering pump market is expected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2026, driven by increasing demand in sectors such as water treatment, chemical processing, and food and beverage industries. Choosing the correct pump not only affects operational costs but also impacts compliance with safety and environmental regulations. With advancements in technology and a wide array of options available, it is essential for professionals to understand the key factors that influence pump performance, including accuracy, flow rate, and fluid compatibility. This guide will outline the critical considerations for selecting a suitable chemical metering pump for your specific application, aiding in making informed decisions that align with industry standards and operational requirements.

Understanding Your Application Requirements

When selecting a chemical metering pump, understanding the specific application requirements is crucial to ensure optimal performance and efficiency. First, assess the type and viscosity of the chemical being pumped. Different chemicals have varying characteristics, such as corrosiveness, temperature stability, and flow rate, which directly influence the choice of pump materials and design. For instance, a highly corrosive substance may necessitate a pump constructed from specialized alloys or plastics to prevent degradation and ensure longevity.

Additionally, consider the required flow rate and pressure settings for your application. Metering pumps are often utilized in processes where precise chemical dosing is vital. As such, understanding the exact flow rates needed during different operational phases can guide you in choosing a pump capable of maintaining consistent delivery, even under changing conditions. Ensure that the selected pump supports the pressure levels needed without risking failure or inefficiency. Evaluating these application parameters will greatly facilitate the selection of a metering pump that not only meets your operational needs but also enhances the overall safety and effectiveness of your chemical handling processes.

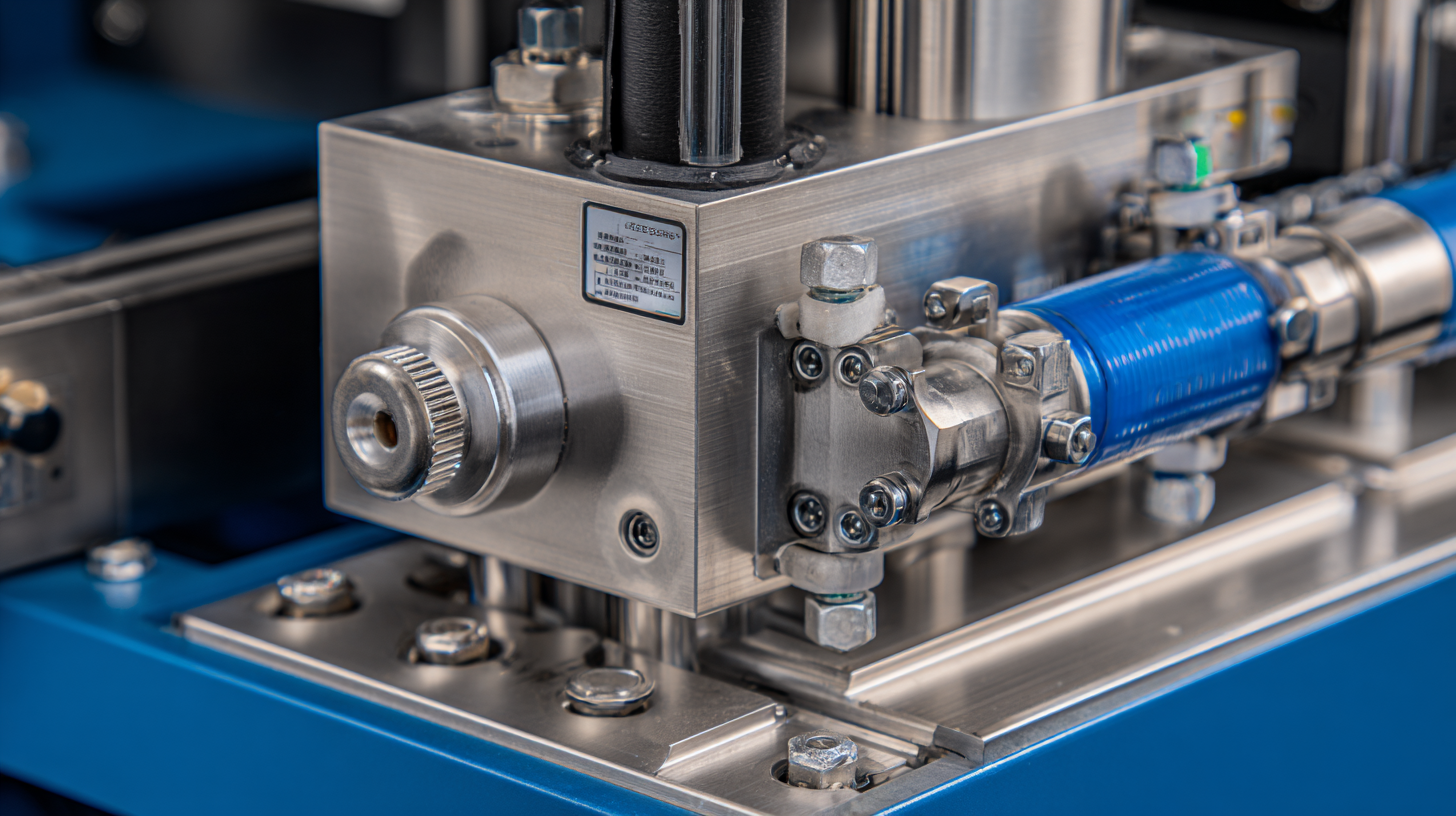

Types of Chemical Metering Pumps and Their Applications

When it comes to selecting the right chemical metering pump, understanding the various types available and their specific applications is crucial. There are typically three main types of chemical metering pumps:

diaphragm pumps, peristaltic pumps, and gear pumps.

Diaphragm pumps, known for their precision and capability to handle hazardous chemicals, are ideal for applications requiring accurate dosing and minimal risk of leakage. As per the latest industry reports, diaphragm pumps are preferred in over 40% of chemical dosing applications due to their robust design and ease of maintenance.

Peristaltic pumps, on the other hand, are widely used in industries such as water treatment and pharmaceuticals, where contamination must be avoided. They work by squeezing a tube containing the fluid, ensuring a clean and safe transfer without risk of backflow. Reports indicate that the market for peristaltic pumps is expected to grow by 6.5% annually, driven by their increasing adoption in critical applications.

Lastly, gear pumps are favored for their ability to handle high-viscosity fluids and are commonly found in chemical processing. Understanding these types’ unique functions and market growth can significantly impact your decision in selecting the most suitable metering pump for your specific needs.

Key Factors to Consider for Pump Selection

When selecting the right chemical metering pump for your application, several key factors warrant careful consideration. First and foremost, it’s crucial to assess the chemical compatibility of the pump materials with the fluids being handled. Different chemicals can cause varying degrees of corrosion or degradation, so choosing a pump constructed from materials that can withstand these properties is essential for long-term performance and reliability.

Another important factor is the required flow rate and pressure for your specific application. Metering pumps are designed to deliver precise flow rates, often measured in gallons per hour or liters per minute. Knowing the required flow rate allows you to select a pump that can adequately meet operational demands without overworking the system or risking under-delivery. Similarly, understanding the discharge pressure needed will help narrow down your options, as not all pumps are capable of handling high-pressure applications.

Evaluating Performance Specifications and Features

When selecting a chemical metering pump for a specific application, it's crucial to evaluate its performance specifications closely. Key parameters to consider include flow rate, pressure capabilities, and accuracy. Depending on the requirements of your process, you may need a pump that can handle high pressures while maintaining precise flow rates. Factors such as the chemical properties of the substances being pumped—such as viscosity, corrosiveness, and temperature—further influence the suitability of the pump. For example, a diaphragm pump may be preferable for transferring corrosive liquids, while a gear pump could be ideal for more viscous fluids.

Additionally, features like control options, material compatibility, and maintenance ease play significant roles in ensuring optimal pump operation. Many modern metering pumps come equipped with advanced control systems, allowing for integration with process automation. This capability can enhance efficiency and reduce manual adjustments. Furthermore, choosing a pump with durable materials can prevent degradation and extend the lifespan, which is particularly important in challenging environments. Thoroughly assessing these specifications and features ensures that the selected chemical metering pump aligns with both the application's needs and the operational goals.

Performance Comparison of Chemical Metering Pumps

This bar chart illustrates the performance of various chemical metering pumps based on their flow rates measured in liters per hour (L/hour). Evaluating these specifications can help in selecting the right pump for your specific application.

Maintenance and Support Considerations for Metering Pumps

When selecting a chemical metering pump, it's crucial to consider maintenance and support to ensure optimal performance and longevity. Regular maintenance practices, such as routine inspections and timely calibration, help identify potential issues before they escalate into significant problems. Proper maintenance schedules can vary based on the pump’s application and operating conditions but include checking seals, hoses, and fittings for wear and tear, ensuring that the pump remains efficient and reliable.

Additionally, having access to comprehensive support services is essential. This includes technical assistance, availability of spare parts, and the capability for routine maintenance provided by the manufacturer or distributor. Establishing a relationship with a reliable supplier who offers training and troubleshooting resources can significantly enhance the lifespan and effectiveness of the metering pump. Understanding the level of support available can influence decision-making, ensuring that the chosen pump not only meets initial application requirements but is also equipped with the necessary backup for ongoing operations.

Related Posts

-

Innovative Solutions for Plunger Metering Pump Applications

-

Unlocking Efficiency: The Significant Advantages of Plunger Metering Pumps in Process Industries

-

How to Select the Right Hydraulic Diaphragm Pump for Your Industrial Needs

-

How to Choose the Best Chemical Pumps for Your Industrial Needs

-

Top Strategies for Sourcing High Performance Industrial Pumps Globally

-

5 Innovative Ways Pressure Pumps Enhance Industrial Efficiency